ACCESS INACTION

42 | ACCESS

in

ACTION | MAY 2014

Manitouhas announced two

new telehandlermodels are in final

development stages at its CastelfrancoR&D

facility in Italy, withoneof thepreliminary

machines said to featurewhatwouldbe

themarket segment’s largest liftingweight

capacity at 40 tonnes.

ManitouAustraliaManagingDirector,

StuartWalker, said: “Manitou is currently

in theprocess of building twonew

telescopic handlers due for introduction

to the localmarket in the second semester

of 2014. At this stage, it’s important to

say the larger of the twomodels has been

designed to safely and repeatedly handle

up to33%more than thehighest-capacity

production telehandler currently on the

market.”

Whenaskedabout themachines’

proposedmarket, Stuart said the company

has placed anewemphasis on size to cater

for thegrowingheavy-industrialmarket

and, in countries likeAustralia and South

Africa specifically, for thehandlingof

conveyor belt reels in themining sector.

Manitoualsodiscussed a fewnew

technologies expected in thenext

generationof heavy lifters.

Two new super-sized telehandlers coming

With thepossibility of custom

attachment design, thenew telehandler

models arebeingdesigned for standard

operationwith forks, jibs, winches,

platforms, tyrehandlers andbelt

reel handlers. New technologieswill

make themachine easier tousewhen

multiple attachments come intoplay by

automatically adapting itsmode to the

selectedattachmentwithout selection

from theoperator.

“Our R&D teamhas designed an

automatic attachment recognition system

tohelp the telehandlers calibrate their

weight limits and envelope tolerances,

whichmeans improved safety in every

application,” Stuart said.

Manitou traditionally partners its high-

end telehandlermodelswith engines from

Mercedes-Benz for best-in-class efficiency

andperformance. Stuart said thenew

modelswill continuewith the tradition

by featuring the automaker’s 7.2-litre, 6

cylinder diesel engines, withoutputs on

the larger telehandlermodel designed for

1,400Nmof torque and240kW (350HP) at

2,200rpm.

Theengineswill bematched to a fully

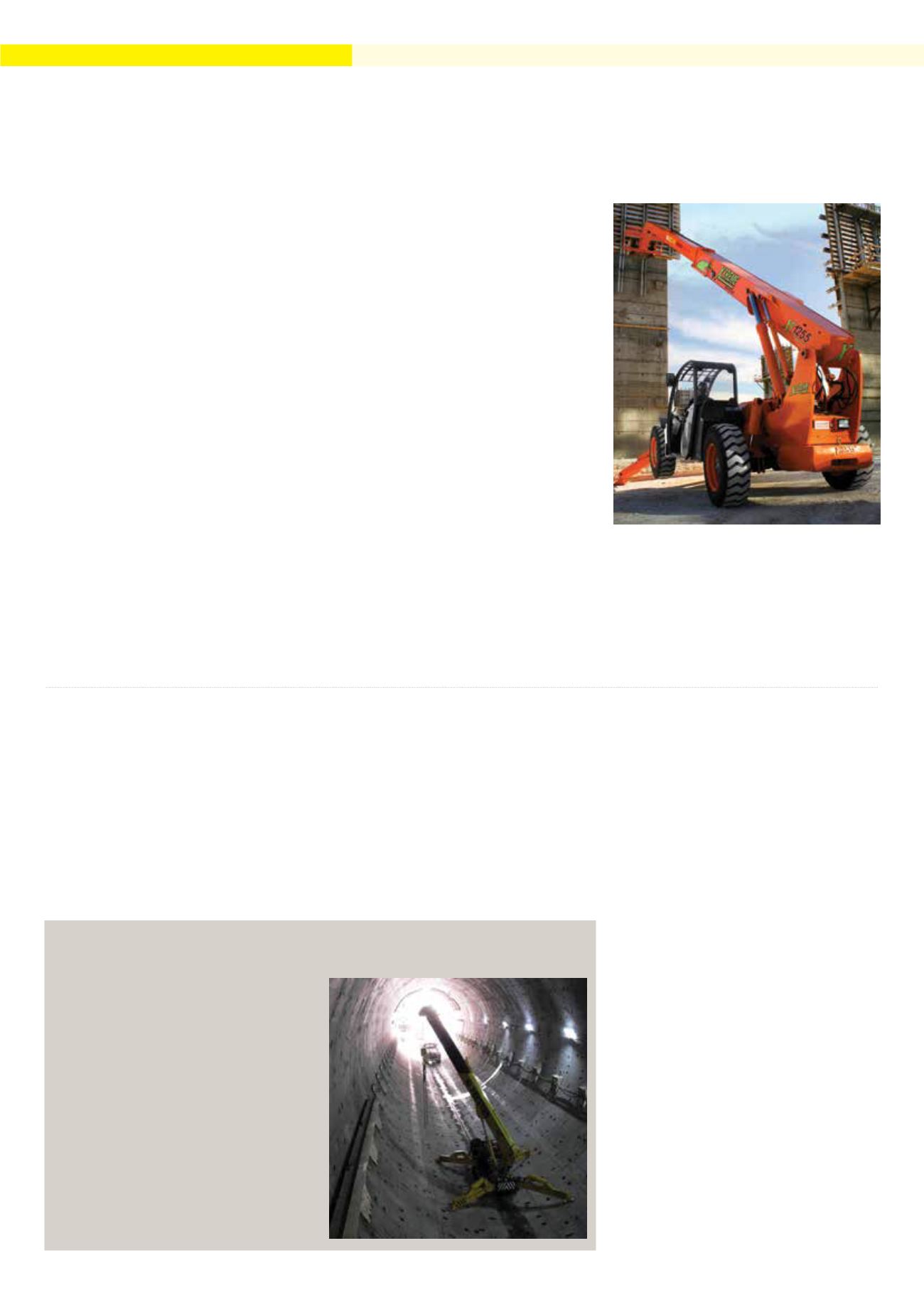

Checkout this great pic! This is Preston

Group’s UNICURW706 spider crane

workingon theAirport Link tunnel job

site inBrisbane. Hiredby Thiess John

Holland, the spider crane assistedwith

the install of beam rails in the tunnel. This

computer controlledmini crawler crane

shows how versatile it is and is oneof

many cranes the small crane company has

in its fleet.

Preston’s compactmini cranes are

designed to fit onto and into tight

construction siteswithminimal impact

andmaximum load capacity.

Formore contact: 1800 440 550or visit:

HR

Spider in a Tunnel –mini crawler

automatic hydrostatic transmission, for

drivingat up to 25km/h.

Manitou’s current flagship telehandler

is theMHT10225, which is able to lift 22.5

tonnes of deadweight, and can extend its

boomby up to 10m.

Contact: ph: 02 9517 3174or visit

website:www.manitou.com.au

HR

Two new telehandlermodels are in final

development stages

PrestonGroup’s UNICURW706 spider crane

workingon theAirport Link tunnel

The TelescopicHandler Associationof

Australia iswarningmembers and the

industry inAustralia tobe awareof the

importanceof tyre replacement and tyre

pressures on TelescopicHandlers.

TSHANational President, StuartWalker

said tyres onTelescopicHandlers are a

critical component and canhave serious

implication to the safeuseof themachine.

The issuewas highlighted in an

article from theNovember issueof UK

publication, Cranes &Accessmagazine

(Vol. 15, Issue 8): “The importanceof tyre

replacement and tyrepressures”.

That articlediscussed research

undertakenby amajor telehandler

manufacturerwhich indicated a5%

reduction in tyrepressure from the

manufacturer’s specified values, can result

ina 30% reduction in capacity at certain

points on the load/height/radius curve

which could result inoverturning.

According to the article: Because tyres

deflect/distort under load they have a

significant effect on telehandler stability

and load carrying ability.

“Anexampleof the importanceof

properly planning tyre replacement

occurredwhena telehandler operator

checked the tyrepressures onhismachine.

Having completed the checks, hewas

walking awaywhenoneof the tyres

exploded. Subsequent investigation

revealed the tyre, whichhad recently

been replaced, was a14plywitha

3.5 tonne load rating, rather than the

manufacturer’s specificationof 16plywith

a six tonne rating. The contractor also

found the tyrehadbeenordered from the

company’s approved supplier by asking for

a tyre for themodel of the telehandler,

withoutmentionof ply or load rating. A

subsequent checkof othermachines found

a thirdof themwere fittedwith incorrect

tyres.” (Cranes &Access Vol. 15, Issue8)

Contact the TSHAon 02 9998 2222or

HR

TSHA reminder of the importance of tyre pressure