ACCESS inACTION

36 | ACCESS

in

ACTION | MAY 2014

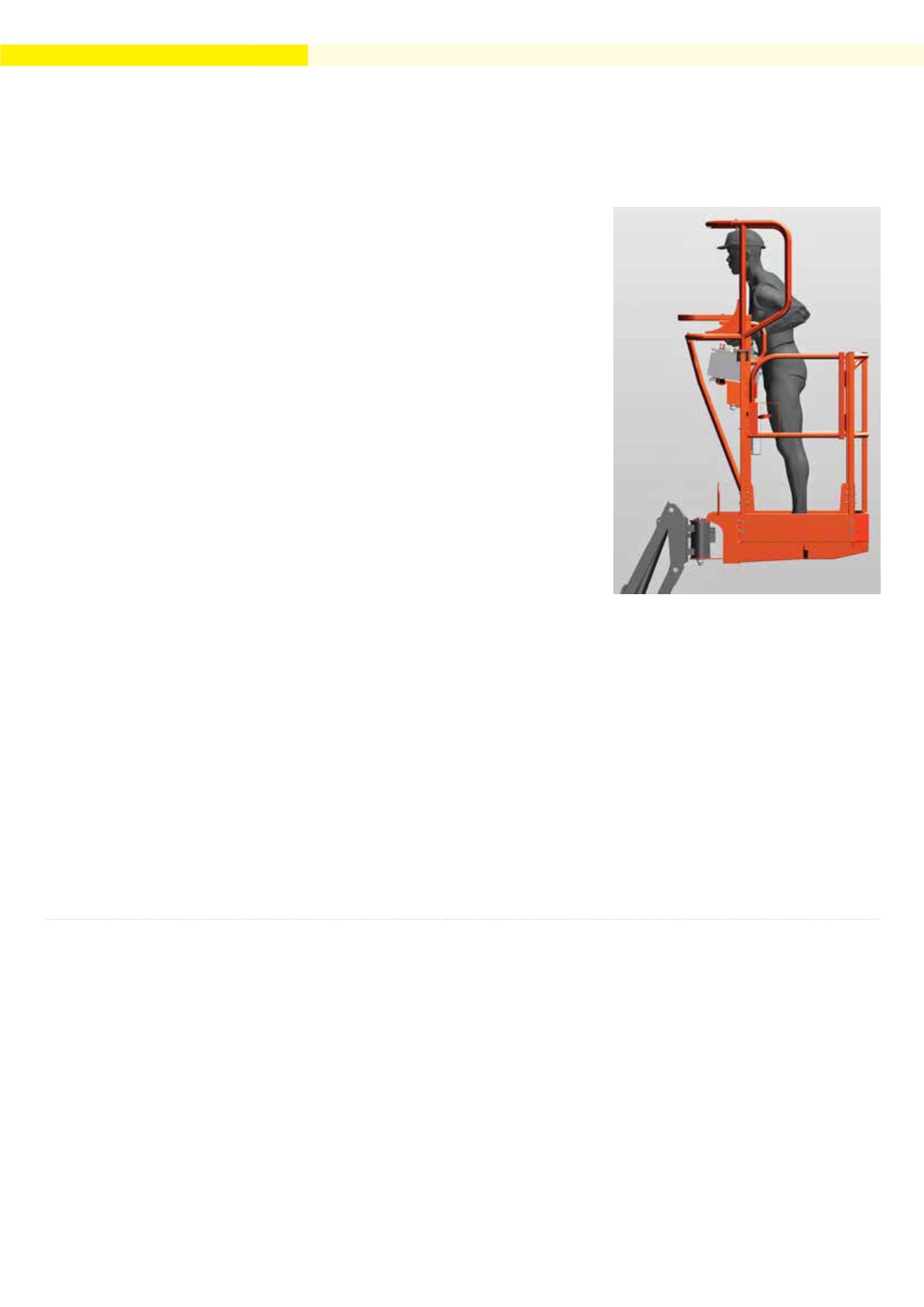

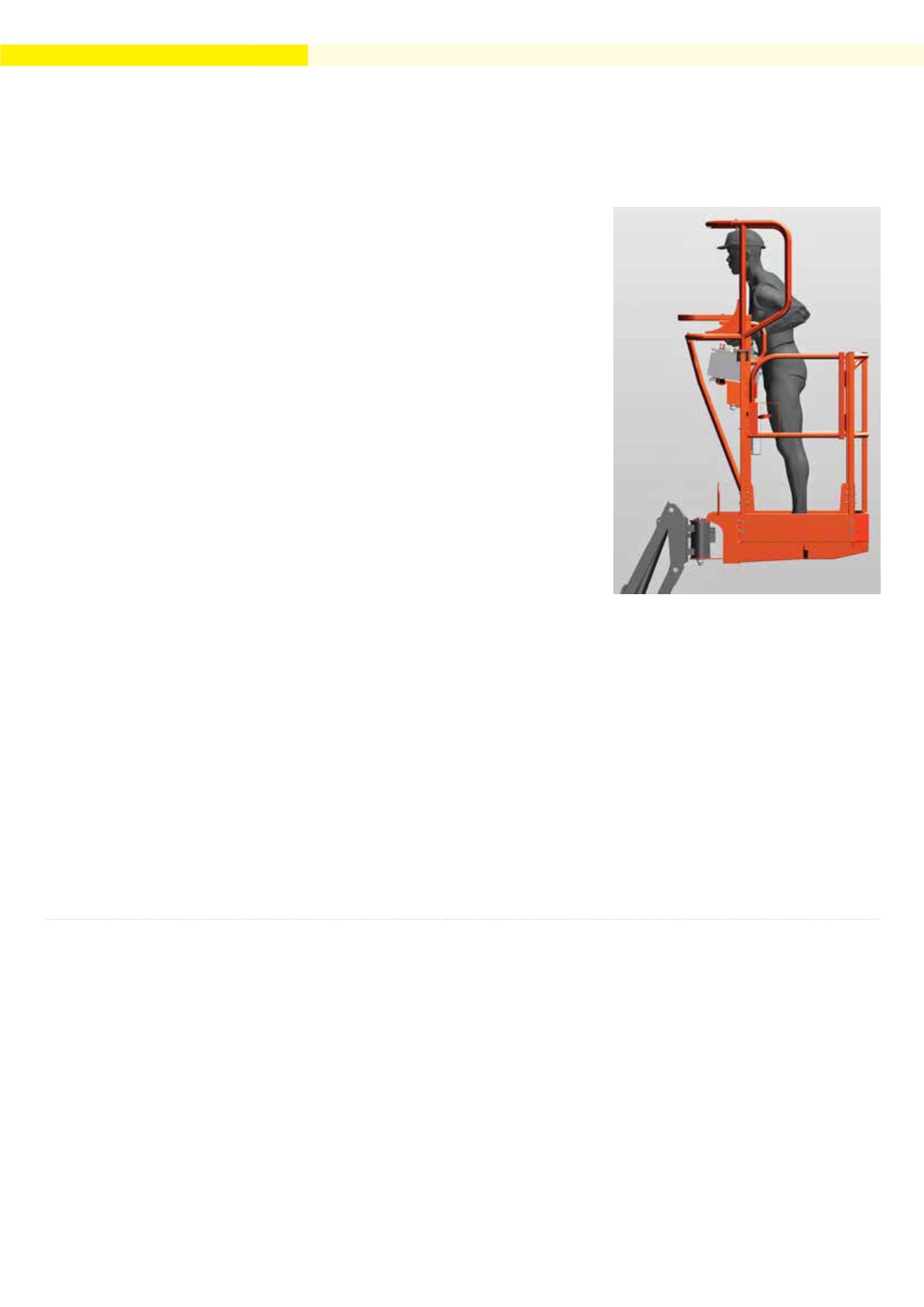

Skyjackhas released twooptions in

secondary guarding (additional protective

measures taken following a job-specific

riskassessment, to reduce thepotential

for sustained inadvertent operation in the

event of collisionwith an external object)

by simultaneously introducing the SG-M

and SG-E secondary guardingmechanisms.

The SG-M is aprotective steel structure

above andover theoperatorwhile the

SG-E emits anaudio-visual alarmwhen the

yellowbar is depressed. If thebar remains

depressed the alarmwill continue to

activate and theenginewill stop, halting

all functions until reset.

This allows the equipment user to select,

following a job specific risk assessment,

themost appropriate solution for any

particular need.

Skyjack said industry groups had

suggested thepossibility of certain

circumstances, conditions andoperations

thatmight result in inadvertent contact

withobstructions anda consequent

unintendedoperationof the controls. A

formof ‘secondary guarding’ is, therefore,

now specifiedby some equipment users.

“Weunderstand there is no ‘one size

fits all’ solutionwhen it comes to such

precautions,”DavidHall, Skyjackproduct

manager Europe said.

“Our telescopic and articulatingbooms

aredesignedwitha rangeof safety

features, in accordancewith regulatory

requirements. However, we recognise this

newmeasure, althoughnotmandatory,

has a role toplay. TheUKgovernment’s

Healthand Safety Executive (HSE) has

welcomed secondary guardingbut has also

notednoone system is appropriate for all

job functions.Weagree, andby offering

Two secondary guarding systems

a choiceof options it broadens theappeal

of secondary guarding to awider range

of customers, whomay consider it a

worthwhile investment.”

The Skyjack SG-M system features a low

weight protective steel structuredesigned

to reduce thepossibility of theoperator

beingheld against the controls in the

event of unintended contactwith an

obstruction.

The Skyjack SG-E system features a

sensor bar that, whenpushed, instantly

stops all functions and initiates an audible

sirenandhigh intensity flashingbeacon.

If thebar is releasedwithinone second,

the sirenandbeaconwill cease, and the

selected functionwill return. If pressure

is applied formore thanone second,

the sirenandbeaconwill continue to

activateand the enginewill stop, halting

all functions until reset. Theapplicable

emergency controls can still beoperated to

bring theplatformdown toground safely.

If the system is accidentally activatedby

theoperator, it canbe easily reset using

the illuminatedbuttonon the control box.

Both the SG-Eand SG-M canbe fitted

onnew Skyjackbooms or retrofitted to

modelsmanufactured in 2006 andafter.

They canbe factory fittedor alternatively

supplied as a kit. Once fitted, neither

system impairs operator visibility,mobility

on theplatformor access to thework area.

Both requireminimummaintenance.

Skyjackworks closelywith customers

whendevelopingnewproducts and

systems. Its SG-Mand SG-E systems have

beendrivenbymarket demand and the

companyworkedparticularly closely

withoneof theUK’s largest equipment

providers (and amajor Skyjack customer)

Select Plant Hire.

To create twoproductswhichmeet all

the customer demands, itwas important

tohave feedback from amajor user, Select

Plant Hire, a companywith almost 30

years of experience supplying construction

equipment. By having Select as apartner,

Skyjackgained extensive insight into

market needs andalsoa ready-madearena

inwhich todo extensive field testing. This

ensured the customer remained the focal

point throughout the testingprocess.

Visit:

HR

Geniehas launched a rangeof on-line

programs todeliver customer support.

GenieOn-Line Technical Training is a

first inAustralia and agreat option for

customers operating in remoteanddistant

locations. Insteadof travelling toattend a

formal Genie serviceprogram inoneof the

capital cities, GenieOn-Line trainingallows

customers to complete a series of training

modules at their placeofwork.

RegMoss, GenieNational Service

Manager said: “Once registered,

technicians are able to complete

introductoryGenie trainingonelectrics,

hydraulics andmachine inspection via the

Flexible online support programs

on-line LearningManagement System

(LMS) beforeattending face-to-face

training.”

ThenewOn-Line Technical Training

programs fromGenieutilise a combination

of video, animation andnarration to

createan interactive learningenvironment.

Launched in January 2014, the response to

the courses has been exceptional, both in

AustraliaandAsianmarkets, too.

Additional courseswill beprogressively

rolledout; the expectation therewill be

20 trainingmodules on linebymid-2014.

TheGenie Parts Portal, another online

support package, was released toGenie

customers in late-2012. The Parts Portal is

anonline systemwhich allows customers

toaccess andorder Genieparts ona24/7

basis. Customers can log in to access data,

viewparts lists, pricing, availability, in

short everything availableby speaking toa

Genieparts interpreter. The real benefit is

customers cangoparts shoppingat a time

that best suits their schedule, day or night,

weekday orweekend.

For greater parts support, customers can

call Genieon the toll freeparts hotline and

speak to aGenie Parts Interpreter.

Formore contact: 1800 788 633or visit:

HR

The steel mountingof Skyjack’s SG-Mprotects the

operator frombeingpinned against the controls

with a solid frame around andover the operator