INDUSTRY IN FOCUS

18 | HIRE

AND

RENTAL

NEWS

| MAY 2014

For several decades Dynapac have

been carryingout exhaustive testingof

different compactionmethods andhave

firmly established thebasic principles of

vibratory compaction, whatworks andwhy

itworks. It iswell established around20Hz

(1,200 rpm) is attained, the acceleration

of gravity is overcomeand amplitudewill

not change irrespectiveof any increase in

frequency. At frequencies below20Hz, the

accelerationof gravity is not overcome

andonly elliptical or evenhorizontal linear

motion canbe achieved – limitedor no

amplitude.

Frequency – is the speedof rotationof

theeccentricweightswithin thedrum,

usually expressed inHz (cycles per second)

or VPM/RPM (vibrations or revolutions per

minute). As discussed above, the frequency

of the eccentricmust begreater than 20Hz

to achieve circularmotion.

With regard to theupper limit, the

frequency needs tobeappropriate for the

amplitude selected.

Correct proportions ofmajor

components

– For both soil and asphalt rollers, tests

of various configurations clearly indicate

that adrum to framemass ratioof 50:50 is

themost effective. A significantly heavier

drum transmits toomuch vibration to the

drum frame, whilea significantly heavier

frameprohibits full displacement of the

drum reducingamplitude.

For soil rollers (singledrum), thedrum

module shouldnot exceed around

70%of the totalmachinemass inorder

tomaintain the tractionand steering

benefits of the tractormodule. Asphalt

rollers (doubledrum) shouldhave a50:50

mass distributionbetween front and rear

modules.

Centrifugal force (FC) has beenproven

tobear nodirect relationship to

theefficiency of compactionby

vibratory rollers. This is simply

the radial forcegeneratedby

rotationof the eccentricmass

and is calculatedbymultiplying

theeccentricmoment (mass x

radius of the eccentric or “m.r”)

by the frequency (in radians per

secondor “

ω

”) squared. Being

a squared function, a small

increase in frequencywill result

ina large increase in centrifugal

force. It is useful for calculating

for the loadon eccentric

Debunking themyths of variable frequency

bearings, but

littleelse.

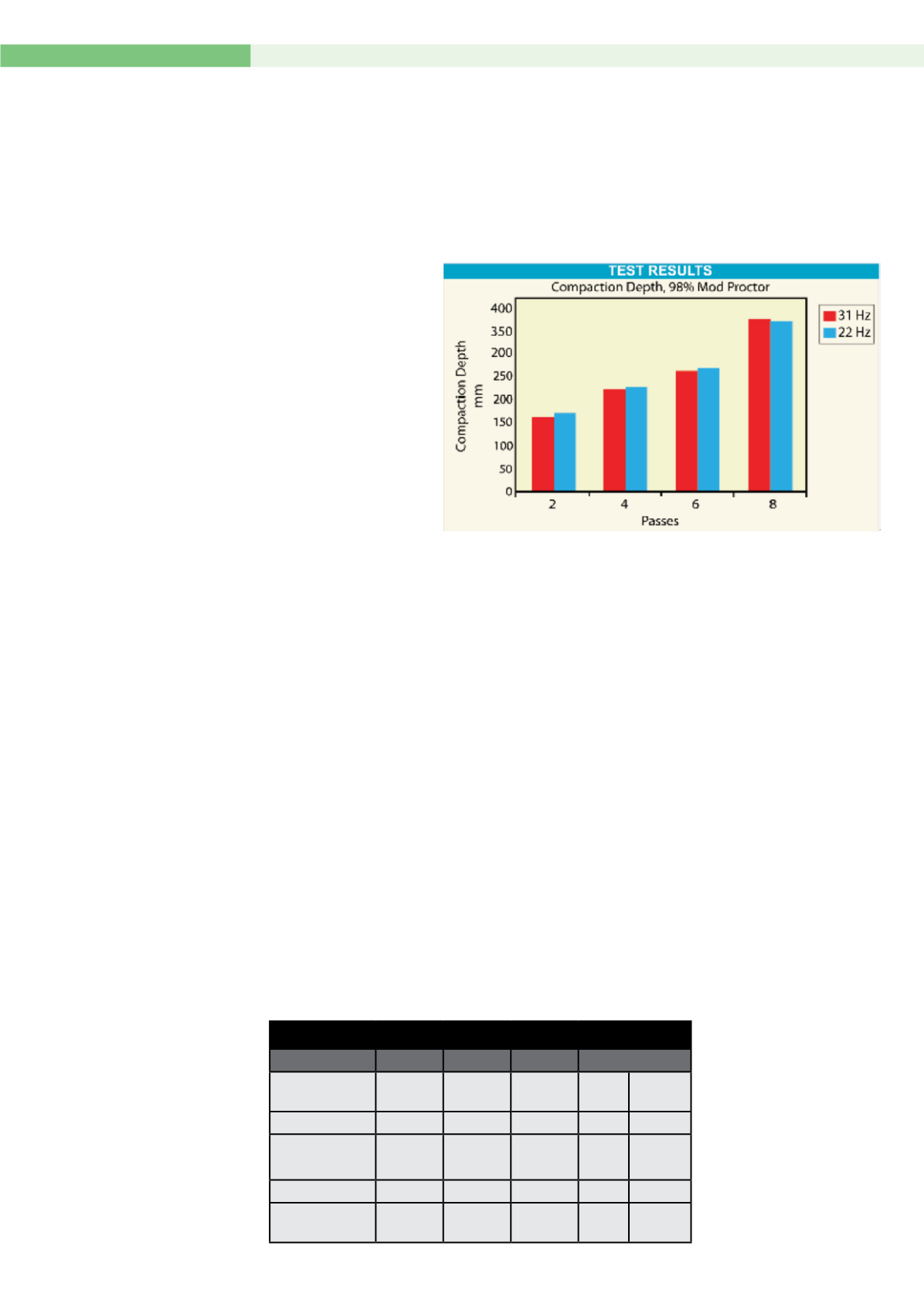

Thegraphs

above illustrate

a test thatwas

carriedout

with the same

roller on the

samematerial

at twodifferent

frequencies.

In the

example

above, where

thedifference

betweeneach

method is

shown tobe statistically insignificant,

there is clearly noadvantage inoperating

at a 41%higher frequency or 98%higher

centrifugal force. These results are typical

for all soil types tested.

What is the correct vibration frequency?

Wehave already demonstrated that a

minimum frequency of 20Hz is required to

achieve circularmotionof thedrum, but

in reality theminimum frequency needs

tobehigher to ensure it does not drop

below 20Hz under varying load conditions.

Usually 27Hz is adequate to ensure

constant circularmotion.

Theupper limit is less obvious and

really comes down to engineeringand

application limitations. Thehigher the

frequency, thehigher the centrifugal force.

Toohigh a frequencywill demand

unnecessarily large eccentric bearings.

Theamplitude (or vertical displacement)

of thedrum is themore important limiting

factor. The further thedrumneeds to

travel in the time allowed, thehigher it’s

mean vertical velocity. Adrummoving

1.7mm in 1/30thof a secondneeds to

movemuch faster than adrummoving

0.85mm in the same timeperiod.

The faster it travels, thehigher the

impact energywhen it comes into contact

with thepavementmaterial.

Toomuch impact energywill causenot

only acceleratedwear to themachine, but

alsodamage to thepavementmaterial,

specifically stonebreakage.

Again, having thebenefit of years of

testing, Dynapac have established that

there is very clear relationshipbetween

vibration amplitude/frequency and

stonebreakage. This relationship canbe

expressedas aunit less constant “K”of 45

whereK=Amplitude/Frequency2.

This constant is not a critical number and

anythingwith a “K” valuebetween25and

65 tends toproduce similar compaction

results. Thehigher the amplitude, the

lower the frequency needs tobe. The

lower the amplitude, thehigher the

frequency canbe. This is irrespectiveof the

material tobe compacted.

Withmodern features suchas Dynapac’s

EcoMode, engine speed canbe reduced

as a fuel savingmeasure.

When engine speed

is reduced, vibration

frequencywill reduce

proportionally. In this

event, thepumpoutput can

be increased tomaintain

a constant frequency.

Operator selected vibration

frequency is of little

value as it has not been

demonstrated that any

frequency ismore suited to

any particularmaterial.

HR

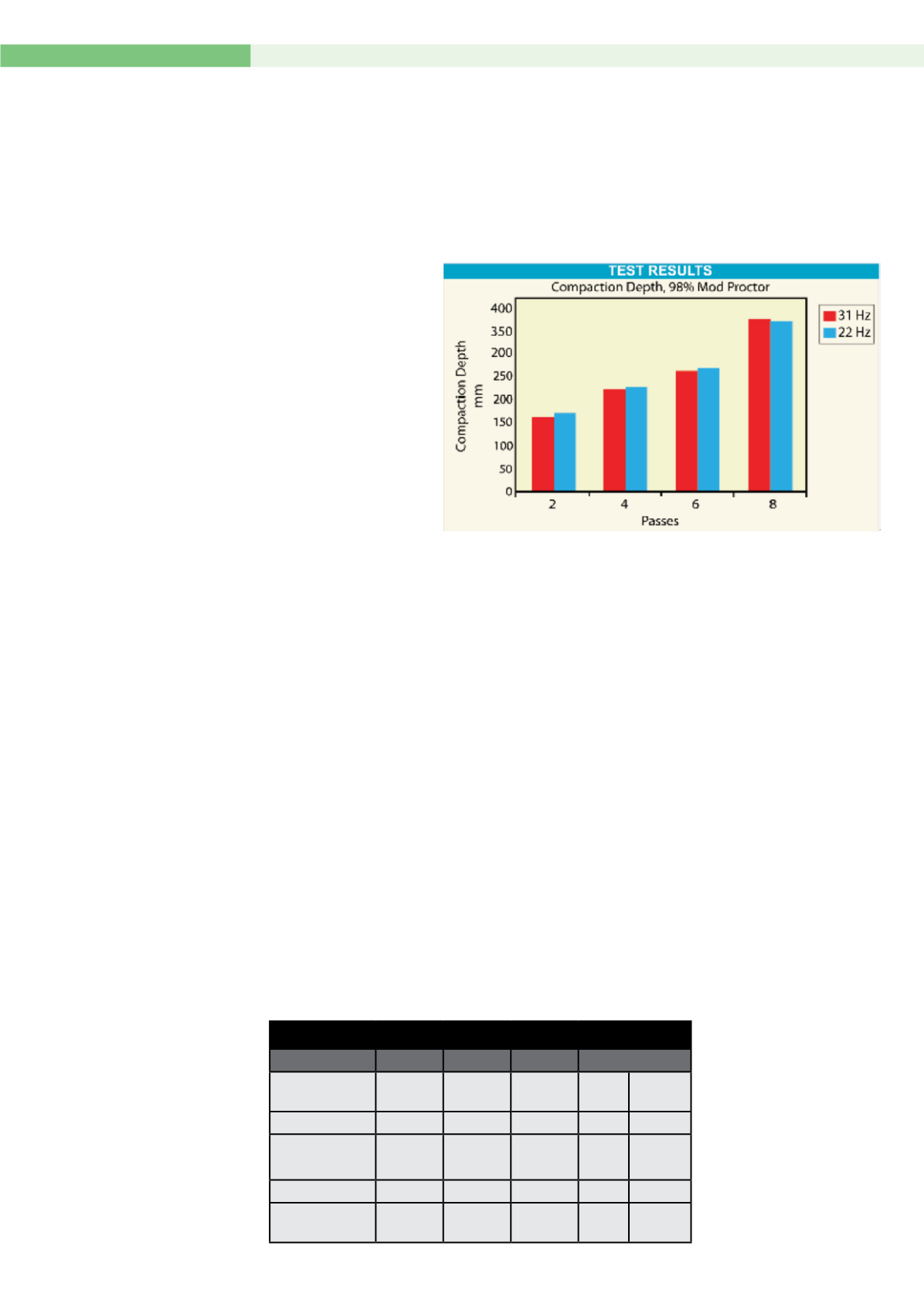

Machine Parameters

Unit

Test 1 Test 2 Difference

Static linear

load

kg/cm 28.0

28.0

0.0 0.0%

Amplitude

mm 1.7

1.7

0.0 0.0%

Eccentric

moment

kg.m 6.1

6.1

0.0 0.0%

Frequency

Hz

22.0

31.0

9.0 40.9%

Centrifugal

force

kN

117.0 232.3 115.3 98.6%

Manymanufacturers of vibratory rollers offer variable vibration frequency either as an

optional or standard featureon their equipment. Theaimof this document is todiscuss the

benefits, if any, of this feature.