40

HIRE AND RENTAL NEWS • AUGUST 2014

ROADS & INFRASTRUCTURE

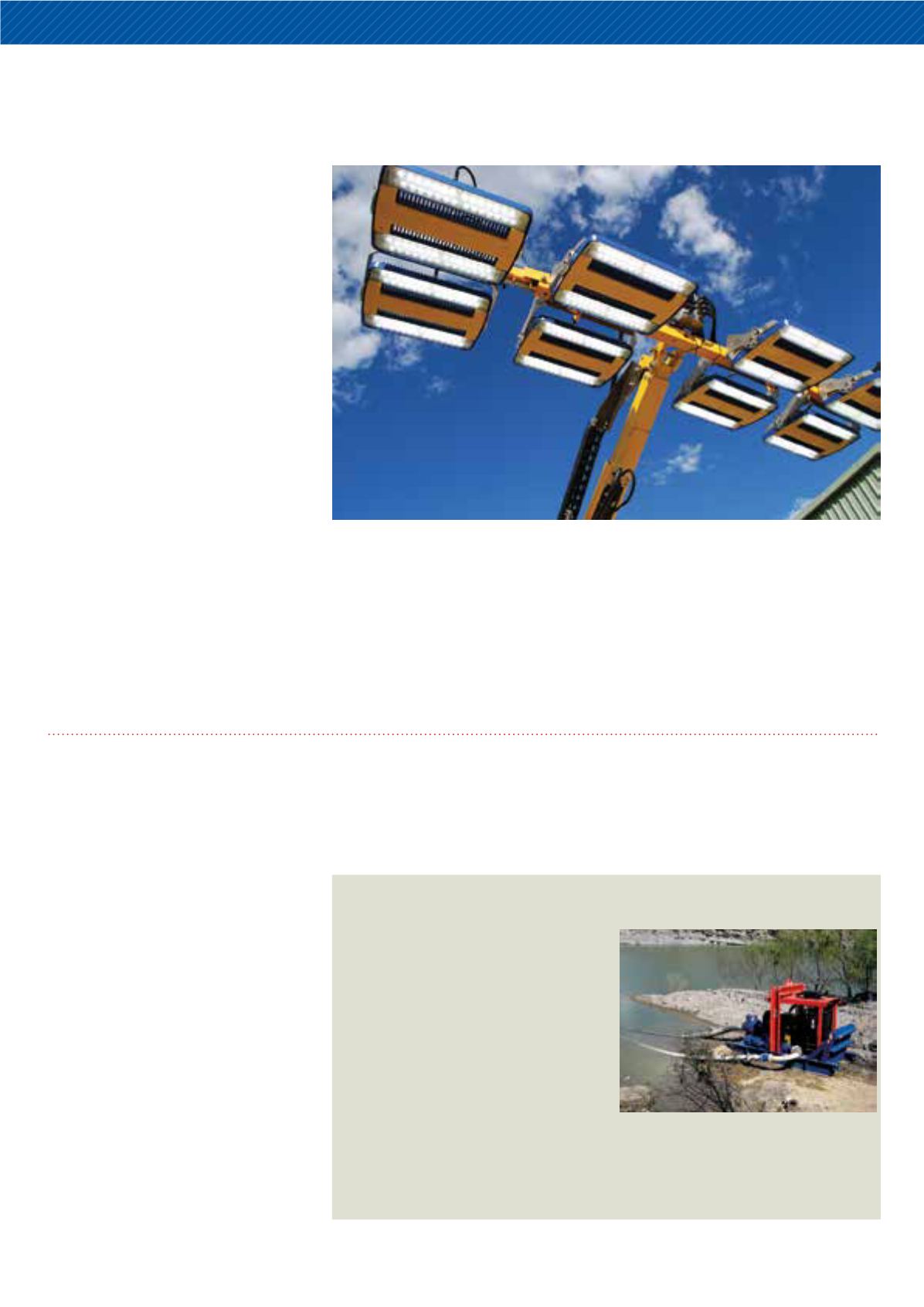

LED mobile lighting tower supplier

AllightSykes has launched a Retro-fit &

Upgrade lifeline to help users of traditional

metal halide towers make the switch

to LED without the trauma of asset

redundancy.

AllightSykes Director of Marketing & Sales,

Paul Sowerby said the success of LED in

mobile lighting applications stems from

the huge efficiency and economy gains it

brings to mining and construction projects

compared with towers which use gas-filled

metal halide lamps.

“More than 10,000 Allight metal halide

lighting towers are operating in mines and

construction and for fleet operators the

evolution of LED risks leaving them with

product for which there could soon be little

or no demand,” Paul said.

“The Retro-fit & Upgrade option means

rental companies and end users can

change to LED even if timing and funding

doesn’t allow them to dispose of their

traditional metal halide units and start

from scratch again. There are four Retro-fit

& Upgrade options and the change-over

can usually be funded from R&M rather

than Capex budgets,” he said.

Powered by a new Perkins two cylinder

500cc water-cooled engine, the Allight

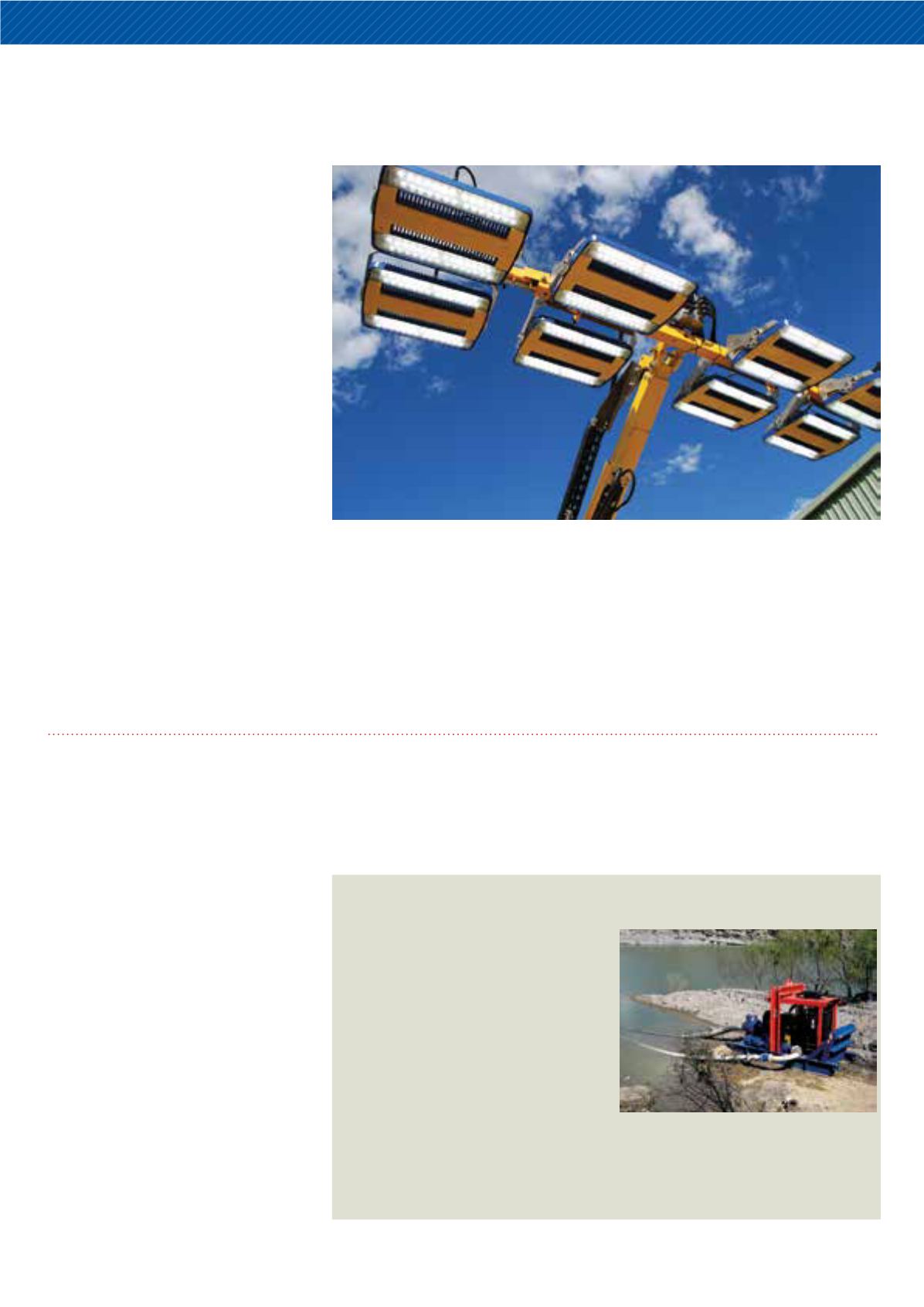

Allight Sykes has a pump range which

has been helping dewater Australian sites

for over 40 years and which has been

designed and built to move millions of

tons of water from mines, quarries, gas

fields and construction sites.

Sykes pumps will:

• Remove the potential contamination

to surrounding water supplies, creeks

and rivers

• Dewater operations quickly and

efficiently to minimise the loss of

production

• Provide expert technical support

for your pump selection and system

Flood pump needed when disaster strikes

Allight LED Retro-fit & Upgrade option combats lighting tower fleet

redundancy nightmare

Allight MS6K-9 Mobile Lighting Tower

LED units need refuelling only once every

three weeks. Eight HELLA lamps can be

mounted on a 9m mast, and the 176,424

lumens they produce provides enough

light for many operating areas. They come

with extended 500 hour service intervals

and deliver an 18t annual carbon footprint

reduction compared with standard metal

halide lamps.

“Having been in the mobile lighting

game for over 20 years, we’ve seen new

technologies come and go.

"For many, putting too much risk before

any reward just isn’t commercially viable

and with the launch of our Retro-fit &

Upgrade solution, even those who can’t

afford to adopt LED, can at least let us help

them adapt to it.”

Contact: 08 9302 7000 or visit:

Pirtek is now the exclusive Australasian

distributor for the entire range of Fast Fill

Systems products.

Manufactured in the USA, all of Fast Fill’s

products are now available through the

113 PIRTEK Service and Supply Centres in

Australia and New Zealand.

Key features of the Fast Fill pressureless

quick fill products are:

• Reduce environmental damage caused

by leaking/spillage

• Provide safety and cleanliness for

servicing personnel

• Eliminate costly spillage of diesel fuel

and other fluids

• Eliminate dirt and dust contamination

in diesel fuel and other fluids

• The reduction in filling time for diesel

fuel and other fluids

Fast Fill Systems was established in

1998 as ‘Nozzletech’ and specialises in

pressureless quickfill units that improve

safety by reducing and eliminating

potential environmental hazards. Pirtek

will also service Nozzletech re-builds as

design with 24 hour spare parts

available from multiple locations and

remote monitoring.

Contact: 08 9302 7000 or visit:

Fast Fill Systems distributed by Pirtek

part of the arrangement with Fast Fill.

For more information contact 134 222

or visit: