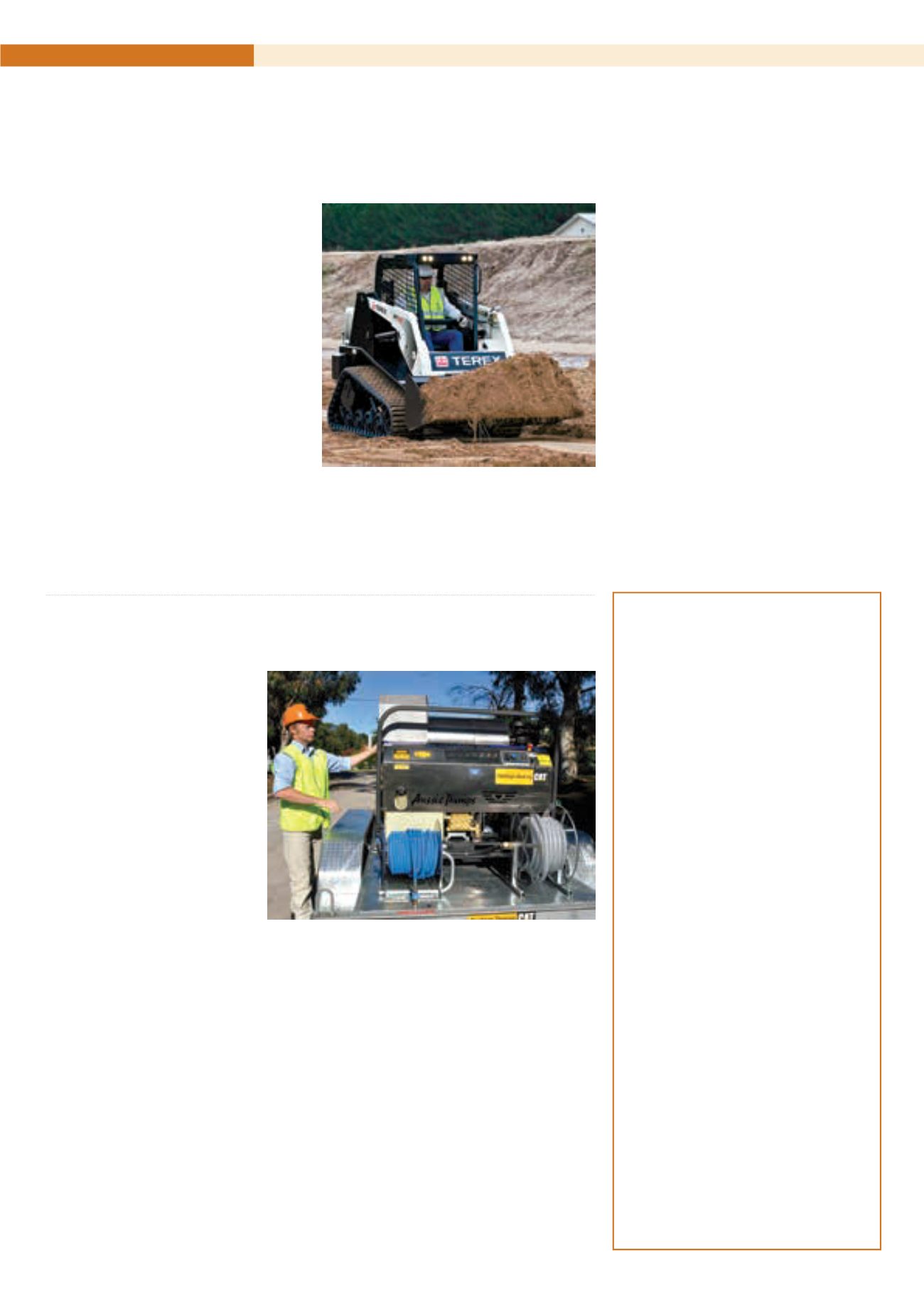

A super heavy duty Aussie

Hydrotek 5000psi steam cleaner

was designed for the Hastings

Deering depot in Tabubil in PNG.

The machine will be used to

clean the range of Caterpillar

plant including dump trucks and

D9s operating in and around the

mine site.

The heart of the big machine

is an Aussie Hydrotek 5000psi

Kubota diesel powered steam

cleaner. The pressure and flow of

the pump, 20lpm flow at 5000psi,

will blow the caked mud off

equipment so service technicians

can maximise efficiency.

The 20hp Kubota diesel powers

a huge triplex pump with ceramic

pistons. The machine comes with e-stop

and a specially engineered stainless steel

rain cap over the burner exhaust to keep

moisture out of the heater coil system.

The Hydrotek delivers up to 130 degrees

Celsius with a variable heat controller

that enables the operator to dial any

temperature from ambient to 130 degrees.

According to Aussie Pumps’ Hamish

Lorenz, most operators seem to run the

machines at around 90 degrees.

“That provides a combination of high

pressure water and very high temperature

without the pressure being dissipated by

the flow turning into steam,” Hamish said.

Steam cleaning plant in mines

Aussie Pumps’ Product Manager, Hamish Lorenz, gives the rig

the final check over before it is shipped to PNG

“The machine comes with a one

thousand litre (270 US gallons) poly tank

equipped with suction filtration. The

stainless steel hose reel is rated to 5000psi

and capable of operating temperatures of

130 degrees C,” Hamish said.

“It comes with 60m of high pressure,

non-marking, 5000psi steam hose.

“The tank, diesel steam cleaner and reels

are mounted on a purpose designed, heavy

duty, hot galvanised trailer. The trailer has

a steel checker-plate floor with excellent

ground clearance for negotiating rugged

terrain.”

For more contact: 02 8865 3500 or visit:

HR

High demand for coal from the New

South Wales’ Hunter Valley coal mines has

had a positive effect on local contracting

businesses including M&M Equipment,

which, established two years ago, has

already added more equipment to satisfy

demand.

“We had a contract for a compact loader

to work in the Ravensworth North mine

to assist with its construction. Since then,

we have been asked to take on additional

work which meant we needed a second

Terex PT-50 Posi-Track Loader Series 3,”

M&M’s Peter McLoughlin said.

“Our machines are being used for the

construction of trenching and associated

tasks. Ravensworth North mine is regarded

as one of the toughest when it comes

to meeting equipment specification

compliance, however the distributor, ASV

Sales, completed all the mine specification

requirements to a very high standard,

Compact loaders at home in coal mine

PT-50 Loader

so we had no problem with achieving

compliance.”

Peter said a second PT-50 was acquired

in February to perform tasks outside the

Ravensworth mine site. Attachments

deployed on this machine include a

trencher, post-hole borer and a tilting

bucket.

“Based on the success with the two PT-50

loaders, we’re now looking to purchase

a third machine. I had previously test

driven a Terex PT-100 machine when it

was released and was very happy with the

performance of its Perkins diesel engine.

“My business partner and I are

mechanics, so we knew what we

were looking for in terms of quality

and reliability of components. As for

serviceability access, the Terex PT-50 ticked

all the boxes.

“Pricing was also competitive; however

equally important to our purchase decision

was support. ASV Sales stocks a complete

inventory of parts and has the right service

facilities, so we knew we would always

have the backup we needed.”

Visit:

HR

A mid-term snap shot on the outlook

for major engineering construction

projects and activity in Queensland, by

BIS Shrapnel has found the State’s civil

and engineering construction industry is

headed for more challenging times than

previously expected.

The report, commissioned by the QLD

Major Contractors Association (QMCA)

and Construction Skills QLD (CSQ), found

the amount of civil and engineering

construction work carried out on major

projects would fall by 53% from 2013/14

to 2016/17 rather than the 40% earlier

predicted.

The report updates the 2013 Major

Projects Report: Queensland Engineering

Construction Outlook released in

February this year.

“Since the 2013 Major Projects Report

was released, economic conditions have

worsened more than anticipated both

at the global and Australian level,” BIS

Shrapnel’s Adrian Hart said.

“Weaker commodities prices coupled

with a high cost base has seen further

project deferrals in the mining sector,

resulting in a weaker major project

forecast over the next two years than

previously anticipated.”

A full copy of the report can be viewed

at:

HR

Major construction

to decline in Qld

22

|

HIRE

AND

RENTAL

NEWS

| NOVEMBER 2013

MINING IN FOCUS