28

ACCESS IN ACTION • FEBRUARY 2016

ACCESS in ACTION

With a large basket capable of hosting

two people or 230kg and a compact

design, the Man’Go 12 is fully compliant

under Australia’s standards and does

not require a licence for elevated

work platform operations because the

machine’s boom length is under 11m

(9.9m precisely).

“Less popular than the 16m access

platforms which dominate the sector, 12m

access platforms meet the requirements

of a compact design but represent an

economical alternative,” Stuart Walker,

Managing Director, Manitou Australia

said.

“With structures more or less equivalent,

the cost difference is not great enough to

justify offering both products for rent. As

most customers do not use the potential

16m, Manitou has been working on a

12m access platform project, which is

economically advantageous, the Man’Go

12,” Stuart said.

“The challenge was to create a

competitive machine while retaining

Manitou’s DNA. It was therefore out of

the question to reduce the safety, quality

or reliability of the machines. To resolve

this problem, Manitou has reviewed

the design of the machine. The solution

involved technical choices which are

a real breakthrough compared to the

standards for articulated platforms.

“First revolutionary change: the

operating mechanism – a redesigned

lifting structure. Instead of a three-part

articulated arm supported by two arms,

Manitou made the choice of lifting the

structure driven by a single arm and a

system of fulcrums favoring speed of

movement. Also, a 1,500mm jib improves

access to the working zone. This overall

structure provides a simplified version

of the elevation part, an elementary

contribution to reducing the total cost.

“Second revolutionary change: the

transmission based on the wheel engines.

The access platform is driven by the

wheel engines. The machine retains

its all-terrain character through control

and management of the distribution of

hydraulic oil in the 4-wheel engines and

differential hydraulic locking on demand.

“Third revolutionary change: the engine

located in the chassis.This engine

position gives a lower centre of gravity,

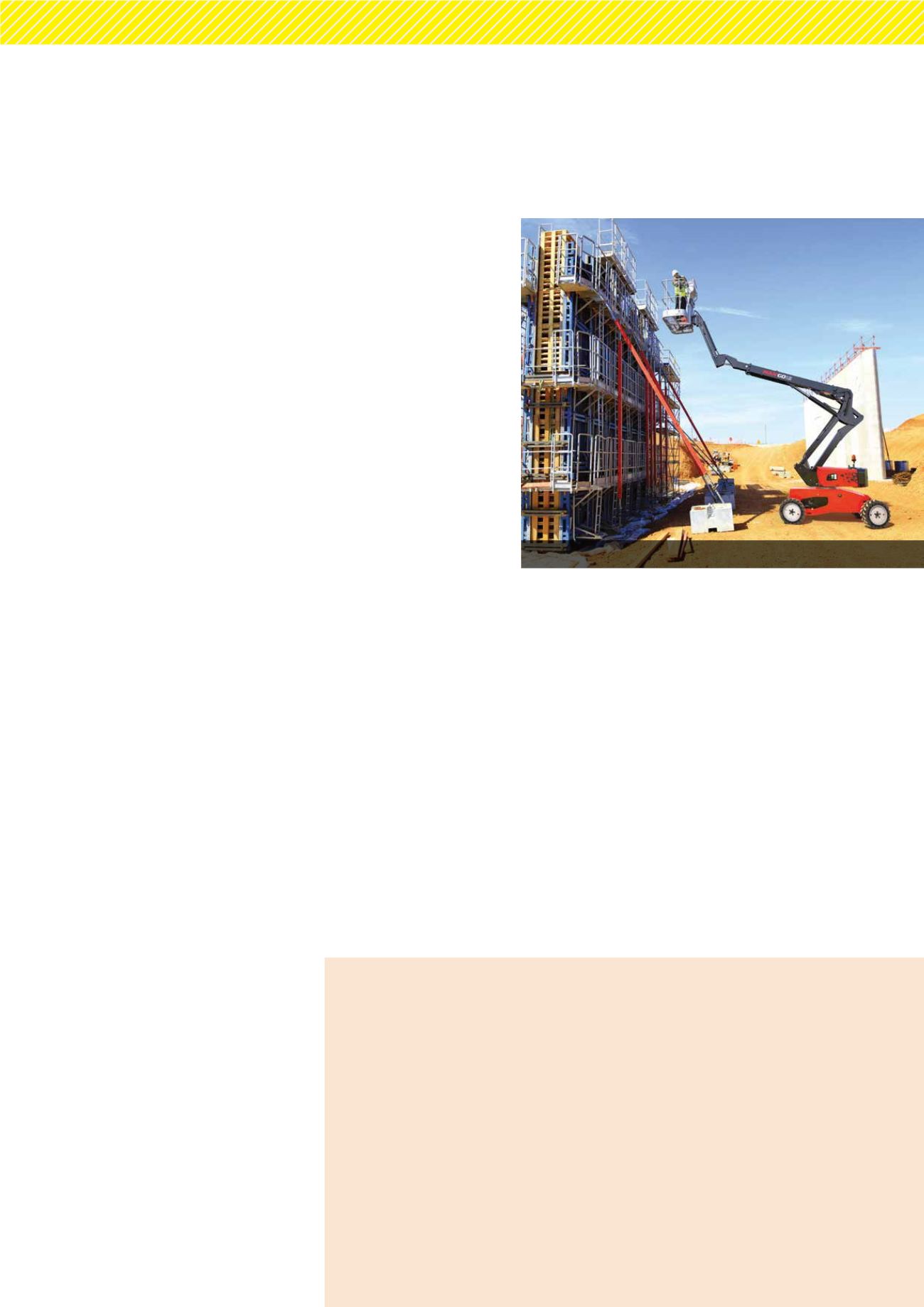

New 12m access platform redesigns Manitou access platform

The new Manitou Man’Go 12 diesel boom lift capable of lifting workers up to 12m

high, is now available in Australia, New Zealand and Oceania.

which contributes to making

the machine lighter. This

design also enabled the width

of the turret to be reduced, to

improve the operator’s view

of the steering wheels; this

significantly improves safety

on congested sites.

“Fourth revolutionary change:

the name of this new access

platform, the Man’Go. Manitou

has put a machine on the

market totally distinct from its

fellow TJ and ATJ machines on

the points mentioned above

and especially in terms of

design and graphical charter.

It would have been easy to

create a 120 ATJ to offer a 12m

access platform to the market.

To fully respond to the specifications of

its rental-company customers, Manitou

had to radically change the design,”

Stuart said.

“To design an attractive access platform,

Manitou relied on technical choices.

Therefore, the Man’Go 12 includes all of

the characteristics of Manitou access

platforms: flexible movements; the

operator’s feeling of safety in the basket;

truck-mounted diagnostic; and all-

terrain ability. This new design also has

numerous advantages:

• Lightness: with a weight close to 4

tons, the Man’Go is about 1 tonne

lighter than competitors, representing

transport savings for rental companies;

• Compactness: at 1.80m width, it is

10cm narrower than its competitors,

and easier to use in restricted

environments;

• Simplicity: operators who are used to

Manitou access platforms easily get

their bearings because the controls in

the basket are standardised with the

ATJ/TJ ranges. The machine only has

one joystick to lift the entire structure;

this will make the machine very easy

to use.

“Low TCO: an attractive purchase price,

transport cost savings, low consumption

thanks to a small engine and electronic

management of the engine speed which

has proven its effectiveness on the entire

internal-combustion-engine range,

simplified maintenance thanks to the

integrated diagnostic system."

Contact: 02 9517 3174 or visit website:

www.Manitou-group.comConstruction Machinery Solutions

has announced its appointment as

authorised parts and service agents for

Merlo Australia.

Based in Brisbane and now into its

seventh year in business, owner

Peter Delaforce has experience in the

telehandler industry and is extremely

happy with the partnership formed with

Merlo Australia. With Merlo’s leading

expertise in design and safety Peter

believes Merlo is the perfect fit for his

business.

“Merlo is able to utilise our service

division with branches in Brisbane,

Toowoomba and Miles in the Surat Basin

to offer parts and prompt service to its

expanding fleet of telehandlers sold

throughout the QLD region.”

Construction Machinery Solutions

provide workshop and field service and

specialise in EWP and telehandler 90 day,

annuals and major inspections.

Contact: 07 3393 9998 or visit website:

www.machinerysolutions.com.auCMS now parts and service agent for Merlo

With a large basket capable of hosting two people or 230kg, the

Man’Go 12 is fully compliant under Australia’s Standards