SAFE at WORK

52

HIRE AND RENTAL NEWS • AUGUST 2016

The standards separate blasters into two

classes for the purposes of differentiating

safe work techniques and level of training

required to safely operate the machines.

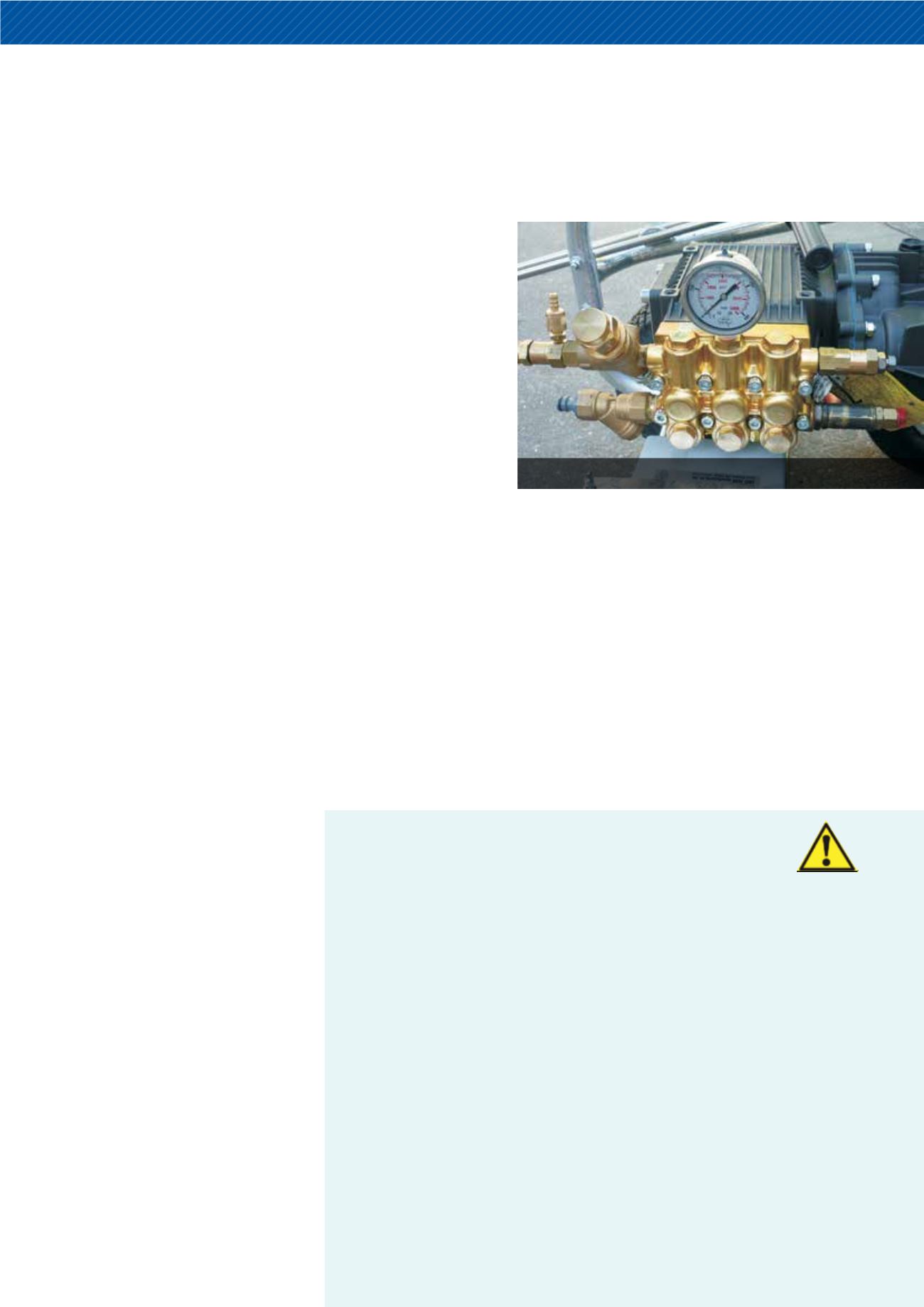

The power of a high pressure water

blaster is calculated by multiplying

the pressure of the machine, in Bar, by

the flow, in litres per minute. Class B

machines include all water blasters above

5600Bar litres per minute. This group

of machines are generally used by big

cleaning contractors. It covers hydro-

blasters up to 50,000psi. However, even

some 3,000psi machines with high flow

rates fall under the Class B category.

Operator training in the safe use of these

machines by an RTO certified trainer is

mandatory under the Australian Standard.

Class A machines are those most

commonly used in the cleaning and hire

industries. These include all domestic and

commercial pressure washers up to about

4,000psi with lower flow rates. The range

covers the big box store domestic style

high pressure cleaners right through to

industrial water blasters traditionally used

for graffiti cleaning, property maintenance

and machinery wash-down.

Class A Operator Training

Australian Pump Industries is aware even

Class A machines can cause operator

injuries. A jet of high pressure water can

carry infections deep into body tissue and

although the surface damage may look

insignificant, resulting infections can lead

to complications.

To educate operators Aussie Pumps

has developed an Aussie Class A Safe

Operator course that covers blaster

basics. The course includes how a piston

pump works, safety precautions required

during operation of a blaster, what can go

wrong and potential consequences.

The Aussie Class A course is available

free of charge in hard copy form. Aussie

Pumps recommends an experienced

operator runs through the course

with trainees to ensure the practical

implications of the training are

understood. The course includes a short

comprehension test and on successful

completion a certificate is issued.

The Aussie Safe Operator range of

PPE protect against pressures up to

7,000psi (500BAR). The range includes

jackets, pants, aprons, gloves and boots.

Aussie Safe Operator free training for Class A blaster operators

According to Aussie Pumps’ Hamish Lorenz, new Australian Standards (AS/NZS4233.1) for

using high pressure water blasters aim to improve safety awareness in the industry.

Comfortable and lightweight,

Aussie Safe Operator gear

protects an operator should

a hose rupture while under

pressure. Hose ruptures and

fittings failures account for

over 90% of all injuries while

using high pressure cleaners.

An operator will naturally

position the high pressure

gun near their chest during

operation so potential for

personal injury is acute.

Aussie Pumps supply 500Bar

hose shrouds that fit over the

hose where it joins the gun.

Hose shrouds are mandatory on all Class

B machines but pressure jets on a Class A

machine can inflict injury.

The quality and design of the high

pressure water washer is also paramount

to the safety of the operator. Built under

an ISO9001 quality system, all Aussie

Pump blasters feature an Aussie ASP

(Aussie Safety Protection) kit. This kit

includes a number of safety devices that

protect the operator and machine.

For example, a safety valve fitted to the

triplex pump relieves excess pressure in

a controlled manner. This protects the

pump and the operator from pressure

spikes. The thermal dump protects the

pump against excess by-pass running.

The unloader controls the pressure to the

gun. All these devices are factory set for

maximum performance and safety.

The Aussie Scud professional range of

contractor pressure washers focuses on

operator safety. By eliminating ‘sharps’

from the frame the hose is less likely

to snag. The frame design enables an

easy-fit hose reel mounting bar and hose

reel to be attached. The OH&S benefits

of adding hose reel with extra length

hose include minimising trip hazards and

improving operator convenience.

Contact Aussie Pumps on 02 8865 3500 or

visit: www.aussiepumps.com.au

Manual Handling:

review of risk

control measures

WorkSafe Victoria has released new

guidance for employers on how to

review and revise risk control measures

for manual handling. According to

WorkSafe Victoria, as an employer, you

must control the risk of musculoskeletal

disorder associated with hazardous

manual handling, so far as reasonably

practicable. If the risk can't be

eliminated, employers must reduce

the risk by implementing risk control

measures following the hierarchy of

control.

WorkSafe Victoria – Safety Soapbox 1

April 2016

Falling from height

figures

Statistics from Safe Work Australia

show more than 6500 workers were

hospitalised following a fall from height

in the three-year period from July 2006 to

June 2009.

This is 9% of all workers who were

hospitalised during this period.

The Work-related Injuries and Fatalities

Involving a Fall from Height, Australia,

October 2013 report shows falls from one

level to another accounted for 23% of the

falls-related hospitalisations during the

three-year period from July 2006 to June

2009.

WorkSafe Victoria – Safety Soapbox 14

April, 2016

SAFETY

NOTES...

To educate operators Aussie Pumps has developed an Aussie Class

A Safe Operator course