51

HIRE AND RENTAL NEWS • AUGUST 2016

SAFE at WORK

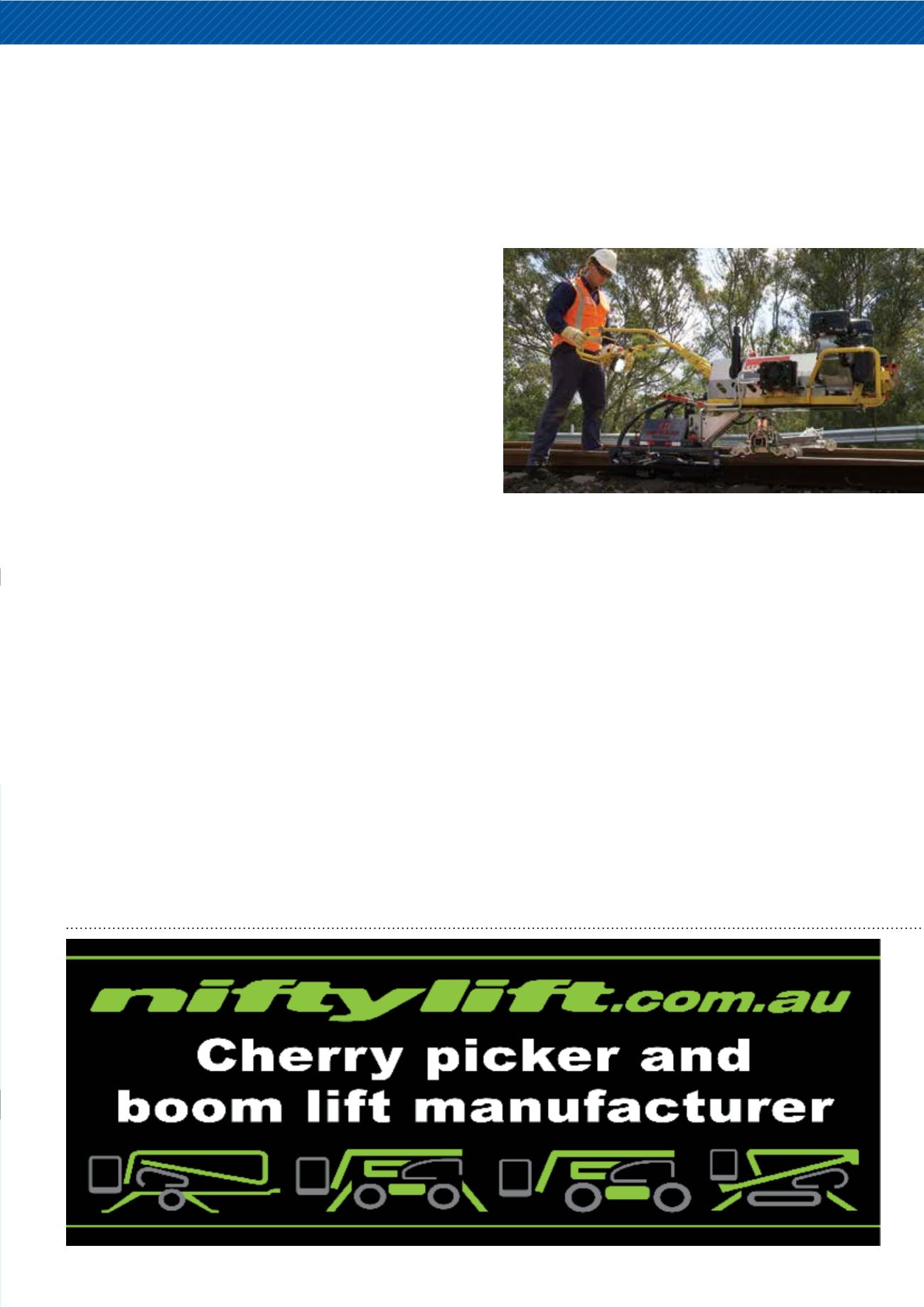

Kennards Hire Rail and partners Hinton

Engineering and Rosenqvist Rail,

developed a new head for applying e-Clip

and other Pandrol fastening systems. The

new technology was debuted at AusRAIL

in 2015.

The new head allows for the automatic

installation and removal of e-Clip, Traklok

and Fastclip fastening systems. The head

is a component of the Rosenqvist CD 200

push behind automated system. Both

systems work under the Rail Industry

Safety and Standards Board (RISSB)

standard.

The idea for the head was developed

when a major rail contractor approached

Kennards Hire Rail to see if a device could

be developed that enhanced workplace

safety as well as increasing productivity.

Up to this point, e-Clip and other Pandrol

fastening systems were often attached

and removed using hand tools. Applying

fastening systems such as e-Clip involves

the application of considerable pressure.

Accidents on site occurred when that

pressure was inadvertently released while

rail staff were using hand tools.

The research and development process

involved Pandrol, the manufacturer of the

e-Clip system and Hinton Engineering.

There are various permutations of the

e-Clip systems, so the head had to be

adaptable. In addition, there is a rail

height profile difference of approximately

150mm between the rail profiles.

Consultation is required with contractors

regarding the weight of their rail, since

Kennards Hire Rail collaborates to create world first

In a world first, Kennards Hire Rail and partners have developed a new system which

negates the need for hand tools and reduces the amount of manual handling needed on

site, increasing the level of occupational safety.

weights can vary from

31kg to 60kg.

Hinton Engineering

was approached to

partner with Kennards

Hire Rail to develop

the new work head.

Hinton Engineering

was chosen because

it has been a supply

partner for Kennards

Hire Rail for three years

and a synergy between

the two companies

exists. Hinton also has

a deep knowledge of the rail industry and

understands what is required to navigate

the different approval processes with

various track owners nationally.

Bruce Durie from Hinton Engineering

said: “The new work head represents a

50% saving in equipment usage; up till

now rail staff had to use one piece of

equipment to install e-Clip fastener and

only one e-Clip could be extracted or

installed at a time and other fastening

systems use one tool to install the

fastening system and another to extract.

The Hercules e-Clip head will install and

extract two fasteners at a time.”

The CD 200 system is comprised of

three components; a power pack, braked

support frame, and the working head.

The head is interchangeable depending

on what fastening system is being used.

The CD 200 system can safely remove the

e-Clip fastener.

Using the mechanical clipping machine,

CD 200, in combination with other

innovative products such as the Vortok

Stressing Roller & 120T Tensor sets, a

maintenance crew is able to achieve

a much larger scope of works in a

scheduled possession than ever before.

Adoption of these new work procedures

is happening nationally and competency

based training packages (developed by

Kennards Hire Rail partner RTO Go Train)

are available for this equipment.

Go Train General Manager Phillip Long

said: “In the past, end users could hire

a complex machine with minimum

instruction. This was not adequate and

could lead to both injury and damaged

equipment. Working with Kennards

Hire Rail and Hinton Engineering will

ensure workers are better trained on the

machinery, and safer on the job.”

Visit: www.kennards.com.au

Kennards Hire Rail and partners have developed a new head for

applying e-Clip and other Pandrol fastening systems