52

HIRE AND RENTAL NEWS • NOVEMBER 2015

GENERATORS, COMPRESSORS, PUMPS

“While many of us would consider the

model ‘isn’t broken, so there’s no need

to fix it’, and 'we’ve always done it this

way’, smart hire companies are moving

forward and gaining a strong competitive

advantage in the industry by changing

their purchasing habits,” Rohan said.

“A case in point is the purchasing of

diesel-driven portable compressors.

We see tens of millions of dollars of

these pieces of equipment sitting in

hire yards across the country, yet there

are alternative considerations you

could make, increasing their value to

your business even when they are not

generating profit.

“A key pillar for success in the hire

industry moving forward is flexibility.

Placing boxed diesel compressors

on existing plant trailers, instead of

purchasing them as trailer mounted units,

has given several hire companies an

improved return on investment (ROI).

Boxed units free up space

“Boxes save valuable space in your

yard, with only one trailer required for

multiple compressors and generators. For

example: your yard staff could place both

pieces of equipment on the one trailer,

increasing utilisation.

“When not on hire, boxed units can be

stacked three high. Using the example of

a boxed CAPS Airman 100cfm portable

diesel compressor over its trailer-mounted

version, the boxed stack would only take

up 10% of the floor space required for the

same amount of trailer-mounted units.

This would possibly be the same with

generators."

Rohan said: ‘’We anticipate companies

could save hundreds of dollars by having

only the cost of the trailer calculated in

stamp duty payable, not the whole unit,

unlike portable diesel trailer mounted

units. By purchasing a registered trailer

from a trailer manufacturer, you can

reduce the frustration that can be caused

with an existing trailer compressor.”

Flexibility

“Being able to multi-purpose hireable

products by offering the same product

in two configurations can reduce your

capital expenses significantly. For

instance, some of your hire customers

Trailing your way to business success

“Are the current models of purchasing your equipment in the best interests of your

hire business?” Rohan McIntyre, Product Manager, Portable Products for CAPS asked.

may prefer a boxed

compressor on its own

since it will be sitting in one

location on-site, while some

will need to move their units

around, so will need it trailer

mounted. Your yard staff can

interchange between both

configurations.

“By purchasing the trailer

separately at a later date, you

can customise the setup to

your satisfaction. You can

identify the trailer style that

works best for your customers

and delivers the business

maximum profitability."

Contact: 1800 800 878 or visit

website:

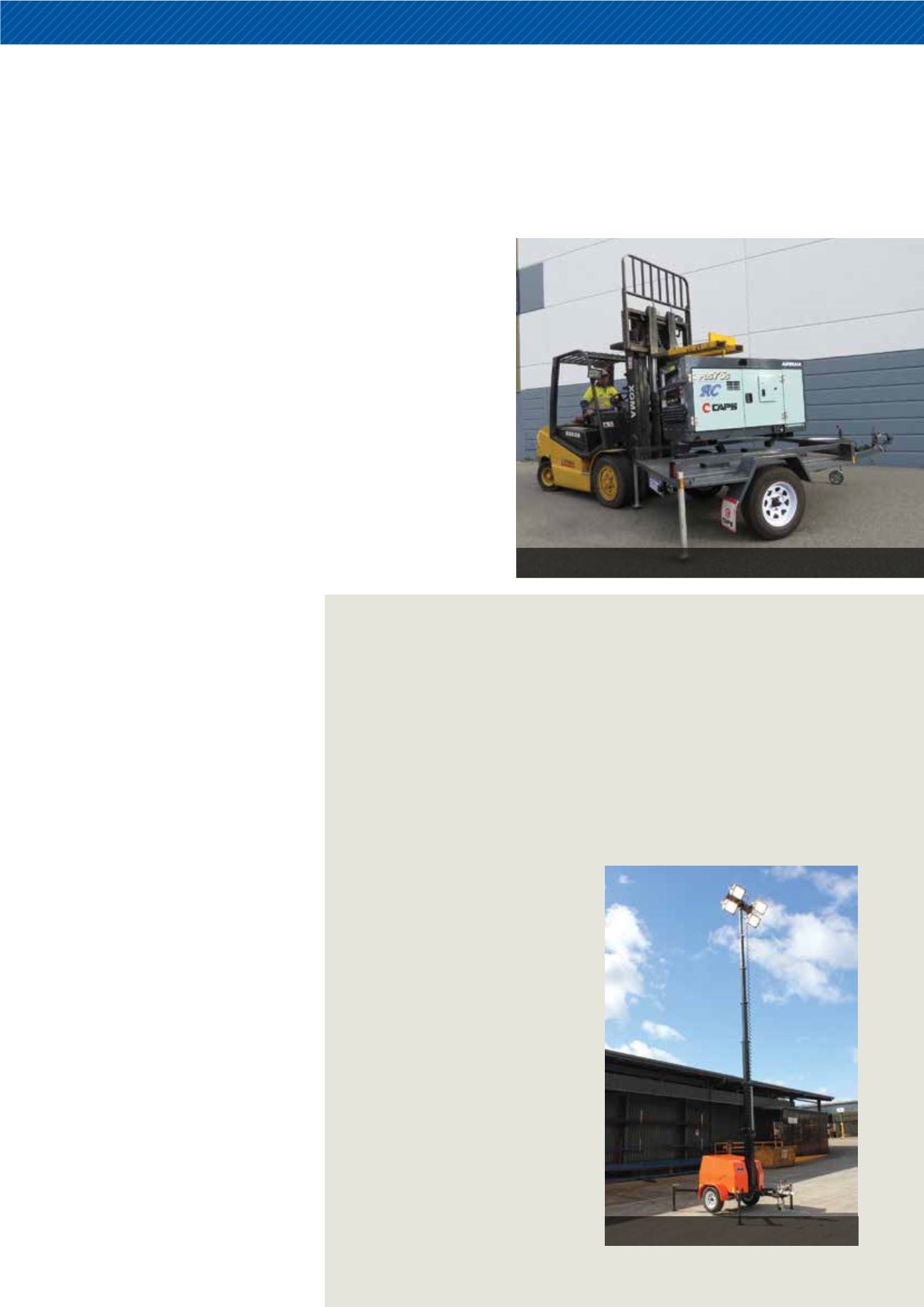

www.caps.com.auA CAPS yard person works to place an Airman diesel compressor

on a trailer

JLG’s new Metro LED Lighting Tower is

purpose-built using ISO9001 standards

in Australia, with features designed to

suit Australian conditions.

According to Arron Cooper, Product

Manager at JLG Industries, results

of recent surveys highlight what is

important to light tower owners: proven

reliability, prompt supply of parts

and service – especially into remote

locations, and transportability.

“The JLG Metro LED will also help users

save on fuel. Extra low voltage, high-

output LED lights, in combination with

fuel-efficient engines and start/stop

controllers, reduce fuel consumption.

“Electricians are no longer needed for

‘Tag and Test’ because the towers have

a 48-volt DC extra low voltage system.

A quick-disconnect light head makes

short work of disassembly. Operators

will find it easier to comply with noise

regulations thanks to the new exhaust

system, sound proofing and quieter

running engines on the JLG Metro LED,”

Arron said.

“JLG Metro LED Lighting Towers are

designed for side-by-side loading on

trucks, allowing seven units to be

transported on a standard semi-trailer, or

11 units at a time on a B-Double.

“The JLG Metro LED can also be

Metro LED lighting tower is purpose built

customised with a host of options and

accessories, many of which are available

in kits,”Aarron said.

“For customer convenience and peace

of mind, all JLG products are backed by

JLG’s Ground Support network. Factory-

trained technicians are available at JLG

workshops across the country or access

the fleet of field service vehicles, all

equipped with IVT and spare parts.”

Contact: 131 554 or visit:

www.jlg.com.auJLG’s new Metro LED Lighting Tower is

purpose-built