According to Webmaster Yoann Grange,

the new

manitou.comwebsite is based

on a set of innovative technologies

that make it one of the most advanced

websites in the handling materials

manufacturing sector.

“The content has been entirely updated

and the interface redesigned,” Yoann said.

Manitou has a wide range of products on

offer in the construction, agriculture and

industrial sectors in over 140 countries

worldwide. Engine norms, adaptations for

countries or professions and options are

all elements that make running a website

more complex.

“Manitou has uncomplicated its website

by offering clients a clear product

catalogue adapted to their geographic

zone and to their profession. Users have

access to a multi-criteria search engine

to build their project and specify which

Manitou offers innovation online with new website

The Manitou Group has launched its new website for its trademark brand:

manitou.com, featuring a new layout, new features, improved availability and

accessibility, utilising local start-ups for the website makeover.

machine is best adapted to their needs.

Each machine page includes a set of

elements to document the search: a

brochure, photos, videos, etc.

“Once the machine has been targeted,

the user can contact a Manitou

representative (dealership, subsidiary or

head office).

“The website also includes new features

that let users view the machine: virtual

cab visits, 3D viewing, displays of

machine/accessory compatibility, PDF

technical file generator. The content has

been enriched with pages dedicated to

news, events, history, etc.

“Technically speaking, the website is

responsive and adaptive: the interface

conforms to the size of the user’s screen

and bandwidth speed used to surf the

website. The technology used on the

website also ensures its availability to a

larger number of simultaneous users. The

audio, video and photo material is hosted

on platforms, which means website

visitors can share more files that help

users gather information.

“This new website, accessible in 10

languages (English, French, Spanish,

German, Italian, Portuguese, Dutch,

Polish, Russian and Chinese), has already

generated requests at a greater daily

volume compared to the former site.

“We are planning to make more changes

like the 'solutions' search, for example a

machine with an accessory and service,

standard and optional equipment for

different material categories, displaying

tables of masts compatible for the masted

trucks as well as the ability to display the

load chart between a machine and an

accessory,” Yoann said.

Visit:

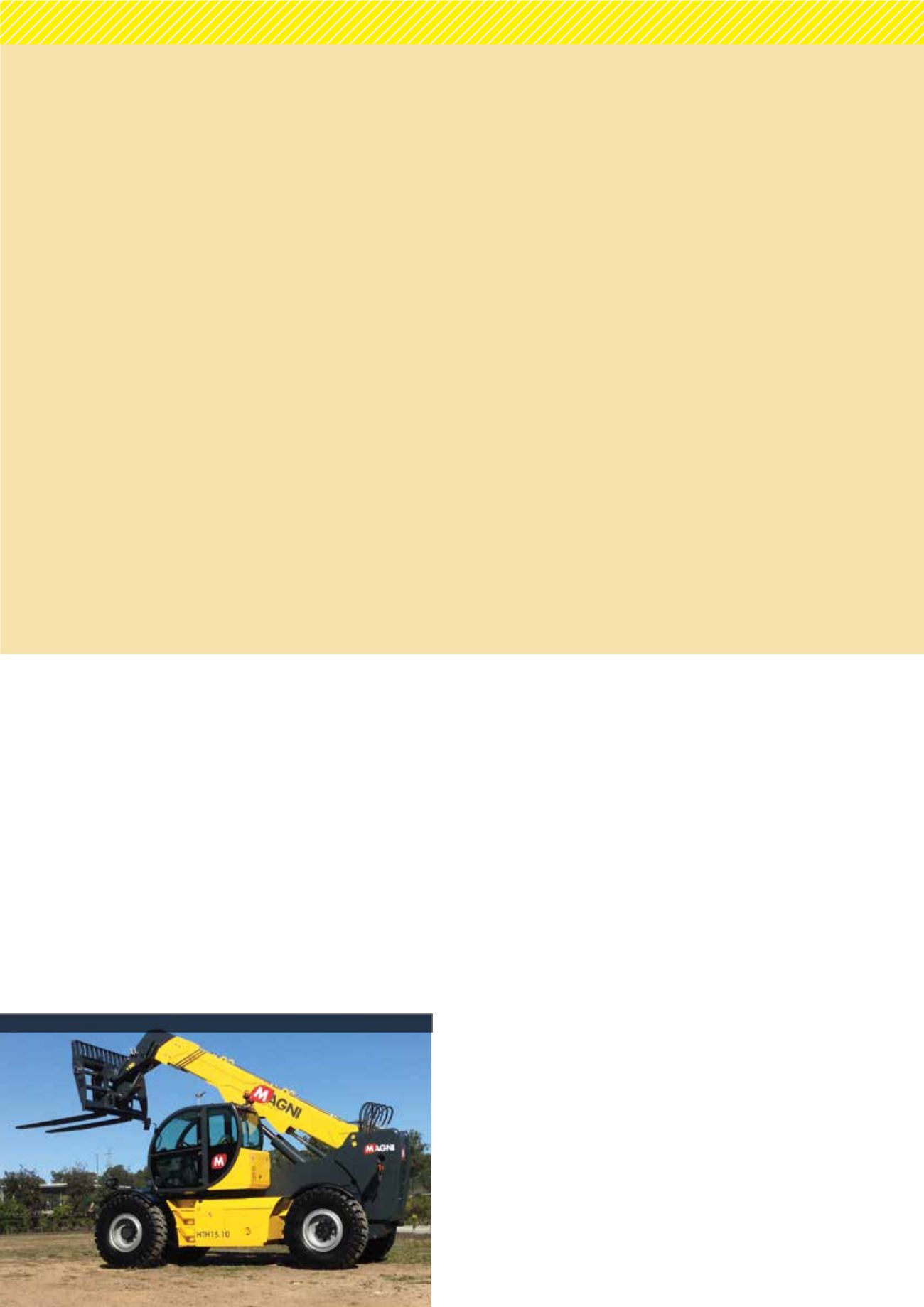

www.manitou.comMagni Telehandlers Australia Product

Manager Greg Sealey said the Magni

HTH line offers the broadest range of high

capacity fixed boom telehandlers in the

market.

“There are nine models, from 10 tonne

capacity and 9.7m lift height to 45 tonne

capacity and 14m lift height. This opens

up a range of mining, resource and heavy

industrial applications for operators and

specialist hire and rental companies

serving those markets,” Greg said.

World’s biggest telehandler now inAustralia

“The HTH telehandlers feature their

own range of high-capacity attachments

designed for heavy duty applications.”

Among those options are three different

fork carriages, one of which is extendible

and comes fitted with a fork positioner.

Other attachments include tyre clamps,

a wheel hub handler, universal cylinder

handlers, strut handlers, rear-hub

handlers and a conveyor belt handler

with 25T capacity.

HTH models up to 20 tonnes are powered

by the JCB Ecomax

engine, with larger

models powered by

Daimler Mercedes

Benz Euro 3 engines.

Magni Telehandlers

Australia also

distributes the RTH

range of slewing

telehandlers, ranging

from 4 to 6 tonnes

capacity and 18-35m

lift height.

“The Magni RTH machines use a JCB

Ecomax engine that delivers fuel savings

up to 10% over competitors and matches

this to an electronically controlled Bosch

Rexroth transmission,” Greg said.

The models can work with a wide range

of attachments including forks, winches,

crane hooks, baskets, platforms, jibs, brick

clamps, concrete kibbles and pipe reels.

“Through their ability to operate with a

wide range of attachments, Magni RTH

and HTH telehandlers can do the work of

several specialist machines like forklifts,

cranes and access platforms,” Greg said.

Magni has a patented safe quick-attach

for changing attachments and each

attachment has an RFID code that allows

the telehandler’s load management

system to identify the attachment and

apply the correct load chart automatically.

Magni Telehandlers Australia offers a

national support network.

Contact: 02 9609 6033 or visit website:

www.magni-australia.com.auA 45 tonne Magni HTH 45.14, a machine distributors Magni Telehandlers Australia

claim is the world’s biggest telehandler, is now available in Australia.

ACCESS IN ACTION • NOVEMBER 2015

42

The Magni telehandler is now available to the Australian market

ACCESS in ACTION