ACCESS in ACTION

TECH

TALK

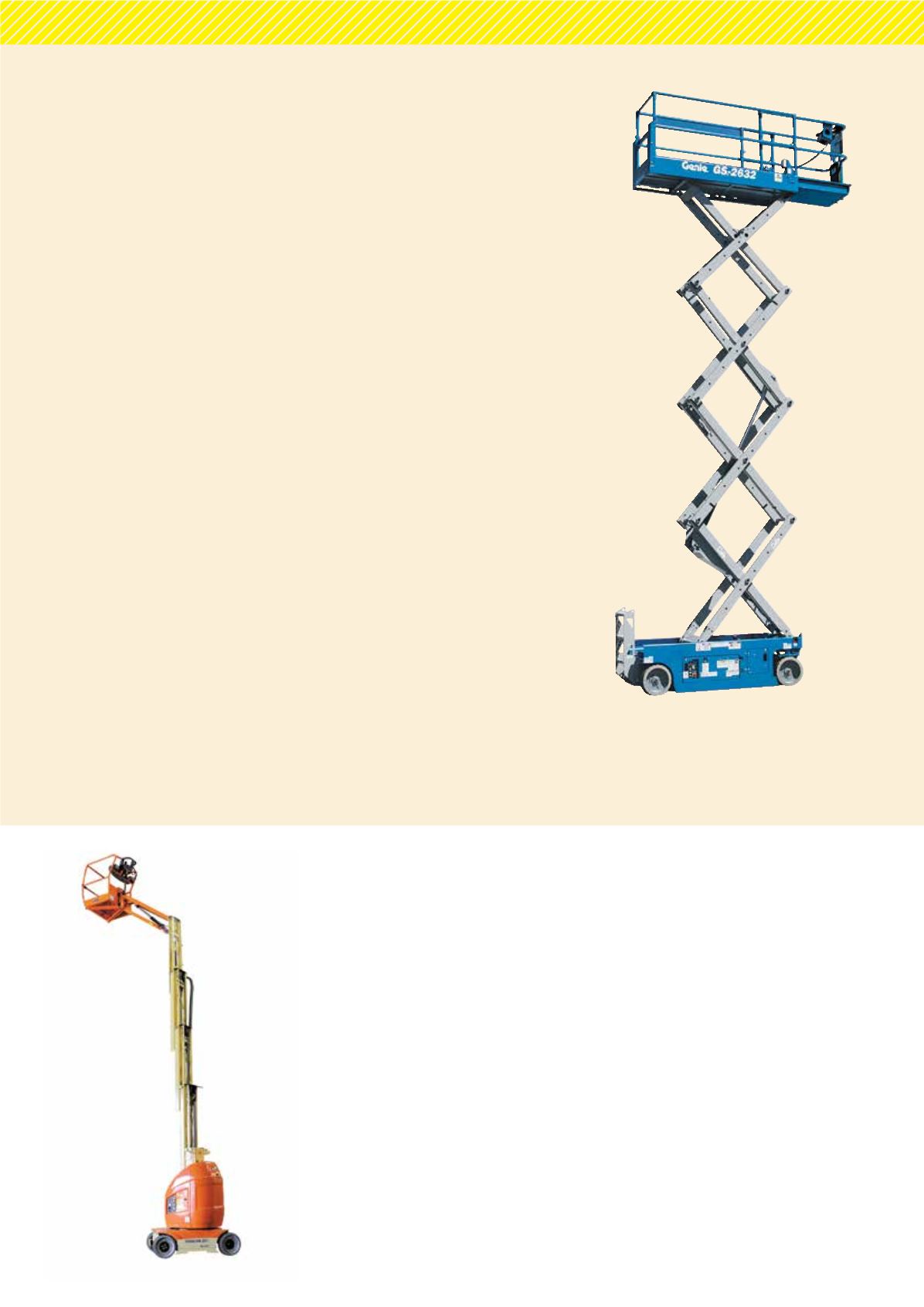

Maintaining productivity of a scissor lift in

sub-zero environments

The growth in food distribution is

creating a demand for utilising scissor

lifts in subzero conditions for facility

maintenance.

Enormous distribution freezers, where

temperatures can drop to minus 40

degrees Celsius, are being increasingly

utilised by the retail sector to warehouse

large quantities of perishable foods.

Often the freezers are massive spaces,

where electric scissor lifts are used for

maintenance.

The trouble is not every scissor lift on

the market is designed to operate in

the artic-like conditions found in these

industrial refrigerators. Therefore, before

committing to a scissor lift, be sure to tick

a number of boxes to help you get the

peak performance from your machine.

Start by checking the machine’s

operating specification is suitable for the

environment. The manufacturer or the

rental yard will be able to confirm if the

design is rated for subzero conditions.

When operating in the chilly confines

of a freezer, it is best practice to plan to

work on the basis of short burst intervals.

Typically this means no more than a

one hour stint in the freezer followed by

another hour on the outside to allow the

machine – and its operator – to thaw out.

This operational imperative will not only

provide safeguards for the machines,

but also for the operators. Operating

elevating work platforms inside industrial

freezers for longer periods will have

a detrimental impact on the machine

battery capacity and the performance of

the hydraulic system.

If the plan involves lengthier work

intervals, it’s important to discuss the

options with the manufacturer. Some

machines will have hard and fast rules

about their operational efficiency in

cold conditions. If the job’s requirement

involves running the machine for

extended periods, there are options

available such as battery warmers and

suitable hydraulic fluid for the application

from most manufacturers of elevating

work platforms.

Finally, a risk assessment is a necessity

– indeed it’s a prerequisite for a scissor

lift whether it is operating in a freezer

or a warehouse. It’s standard practice to

complete a risk assessment that identifies

the hazards encountered by operators

during the scope of works.

For more information about

choosing a scissor lift suitable for

operating in an industrial freezer,

contact: Mitch Ely, Terex Aerial

Work Platforms Ph: 1800 788 633 or

www.genielift.com.auProviding a safer and more productive

alternative to ladders, the T10E has a

platform height of 8.10m, a horizontal

reach of 3.08m and with an up-and-over

reach height of 6.51m.

The T10E has a proven, see through

forklift style mast and a 1.6m jib boom for

access to difficult to reach places.

With a platform capacity of 200kg, the

low maintenance steel platform with

non-skid mesh floor and rear-entry

slide-bar provides a safe, stable working

environment for two people indoors and

out.

Ease of operation and manoeuvrability with mast lift

Fully proportional drive with slew joystick

control and integral thumb-steer switch

provides precise positioning in confined

spaces.

Drive via the rear wheels through

brushless AC motors, reduction

gearboxes and spring applied brakes to

non-marking tyres provides outstanding

gradeability of 25%.

The T10E is powered by a 24v DC traction

battery with integrated, automatic

inverter type charger.

Contact: 131 554 or visit website:

www.jlg.com.au40

ACCESS IN ACTION • NOVEMBER 2015

Compact, powerful and efficient, JLG’s Toucan Vertical mast lift – the

T10E Electric Toucan – runs on battery electric power, and is ideal for

a range of indoor and outdoor applications.