EQUIPMENT SHOWCASE

There are three models, with each model

superseding an equivalent model in the

Power Equipment range. The models are

the PE-NANO (supersedes the EC-90),

the PE-MANUAL (supersedes the EC-

150) and the PE-AUTO (supersedes the

ACP-200).

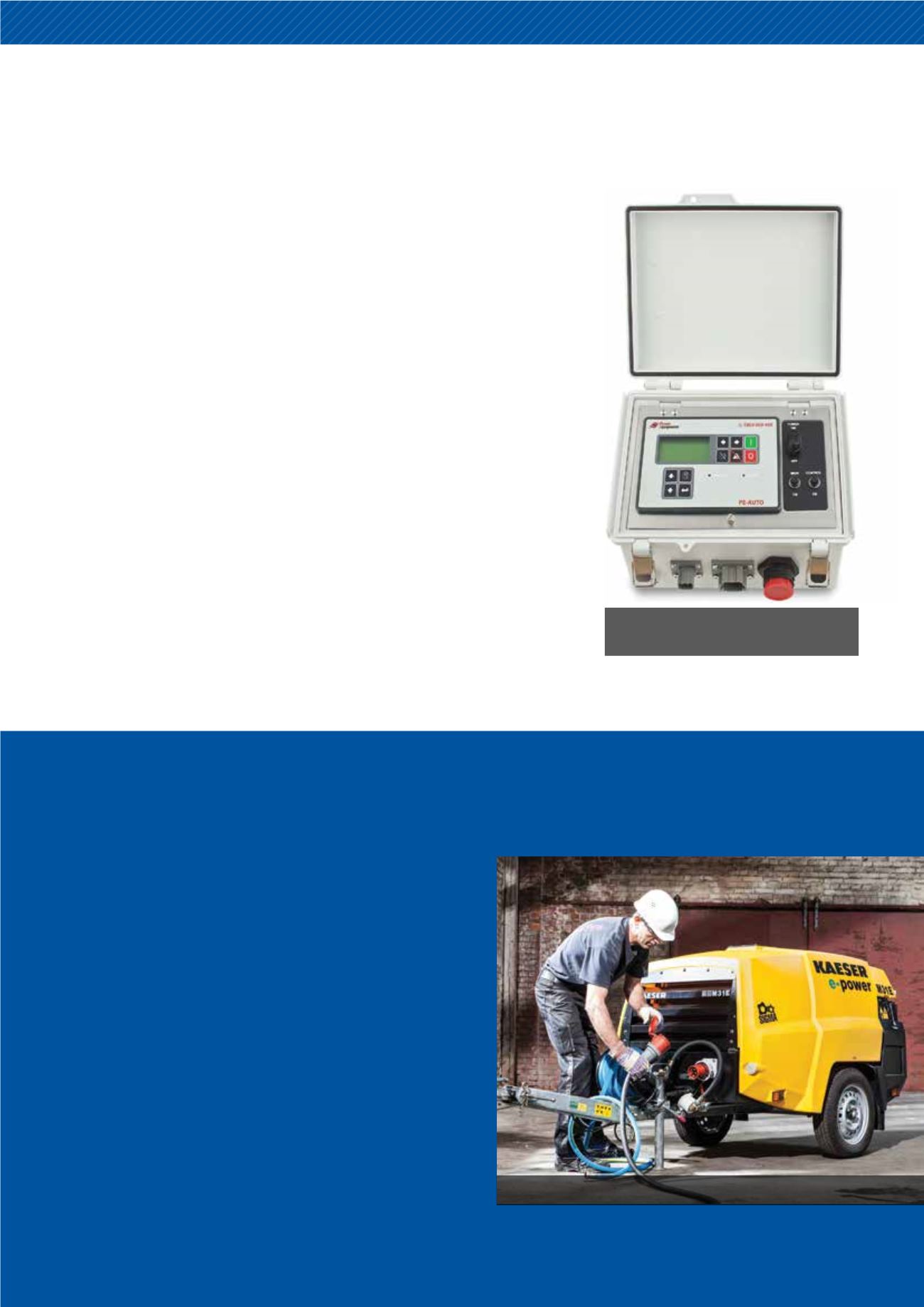

The new range of Engine Controllers

represents a significant upgrade in

technology, functionality and physical

appearance. The sturdy case on the PE-

Manual and PE-Auto has a weather seal

to protect against dust and water. The

PE-Nano, even without a case, is rated at

IP65 for longer protection.

“Our goal has been to make the new

controllers as simple, reliable and easy to

use as possible,” Noel Heritage, Business

Manager at Power Equipment said.

“The superseded range of Power

Equipment Engine Controllers had been

in production for some years, so it was an

ideal time to undertake an upgrade.”

The features across the new range of

Engine Controllers vary. The PE-Nano

controller has keyless start and stop,

oil pressure and coolant temperature

New line of engine controllers to support diesel engines

Power Equipment has launched a range of Engine Controllers to support Yanmar and JCB

industrial diesel engines.

protection plus optional low coolant

level and a water-in-fuel sensor for JCB

engines.

The PE-Manual controller takes the

functions of the PE-Nano and includes

extra functionality of two wire start/

stop, twin float start/stop, fuel pump

pressure monitoring and protection, loss

of prime, 99 hour run timer and for JCB

applications only, water-in-fuel.

The PE-Auto controller goes further

than the PE-Manual with the addition

of seven day repeatable start/stop timer

and individual daily start/stop. Power

Equipment will also roll out added

optional features on the PE-Auto unit

from July 2016. These include Remote 3G

monitoring and control telemetry.

In response to customer demand, the

“Remote Stop Shutdown” feature with

current Engine Controllers is no longer

standard. It can be ordered as a plug in

option across all three new controller

models in applications where required.

As an aid to reliability, the previous two-

piece control harness has been replaced

by a new design, one piece 2m long

The new PE-AUTO Engine Controller is the

top of the range model in the 3 model Power

Equipment range

wiring harness.

Contact: 03 9709 8500 or visit website:

www.powerequipment.com.au

The new electric portable compressors

from Kaeser, are powered by motors rated

at 15–25kW and form part of the family of

Mobilair M27, M31 and M50 compressors.

These machines are ideal for

environmentally sensitive areas such

as clean air zones or building sites

near hospitals, tunnel construction or

as bridge compressors for industrial

stations. Kaeser said electric compressors

make sense since electricity is generally

cheaper than diesel fuel and electric

compressors cost less to maintain.

The IE3 premium efficiency motors, meet

the IP55 enclosure and Class F insulation

standards, as well as comply with and

exceed prevailing Australian GEMS

regulations for 3 phase electric motors.

The Mobilair electric portable

compressors are equipped as standard

with the advanced Sigma Control Smart

Electric portable compressor range with zero emissions

controller and Kaeser`s

patented Anti-Frost

Control. The Sigma Control

Smart makes set-up

and operation – such as

pressure adjustments –

quick and simple with

an easy-to-read colour

display and the Anti-Frost

Control protects tools from

frost and corrosion.

The models are

available with a choice

of a rotational moulded

polyethylene or metal

enclosure and in both

road-going and stationary

versions. Flow rates range

between 2 and 5m³/min

for pressures from 7 to

14bar.

Contact: 1800 640 611 or visit website:

www.kaeser.com.au

Kaeser has launched its Mobilair electric portable compressor range which delivers zero

emissions and savings in operating costs, wherever a power supply is available.

The new electric Mobilair from Kaeser: zero emissions and substantial

savings in operating costs

60

HIRE AND RENTAL NEWS • AUGUST 2016