42

ACCESS IN ACTION • FEBRUARY 2017

ACCESS in ACTION

This could result in the vehicle

overturning. Tyres deflect/distort under

load and they have a significant effect

on telehandler stability and load carrying

ability.

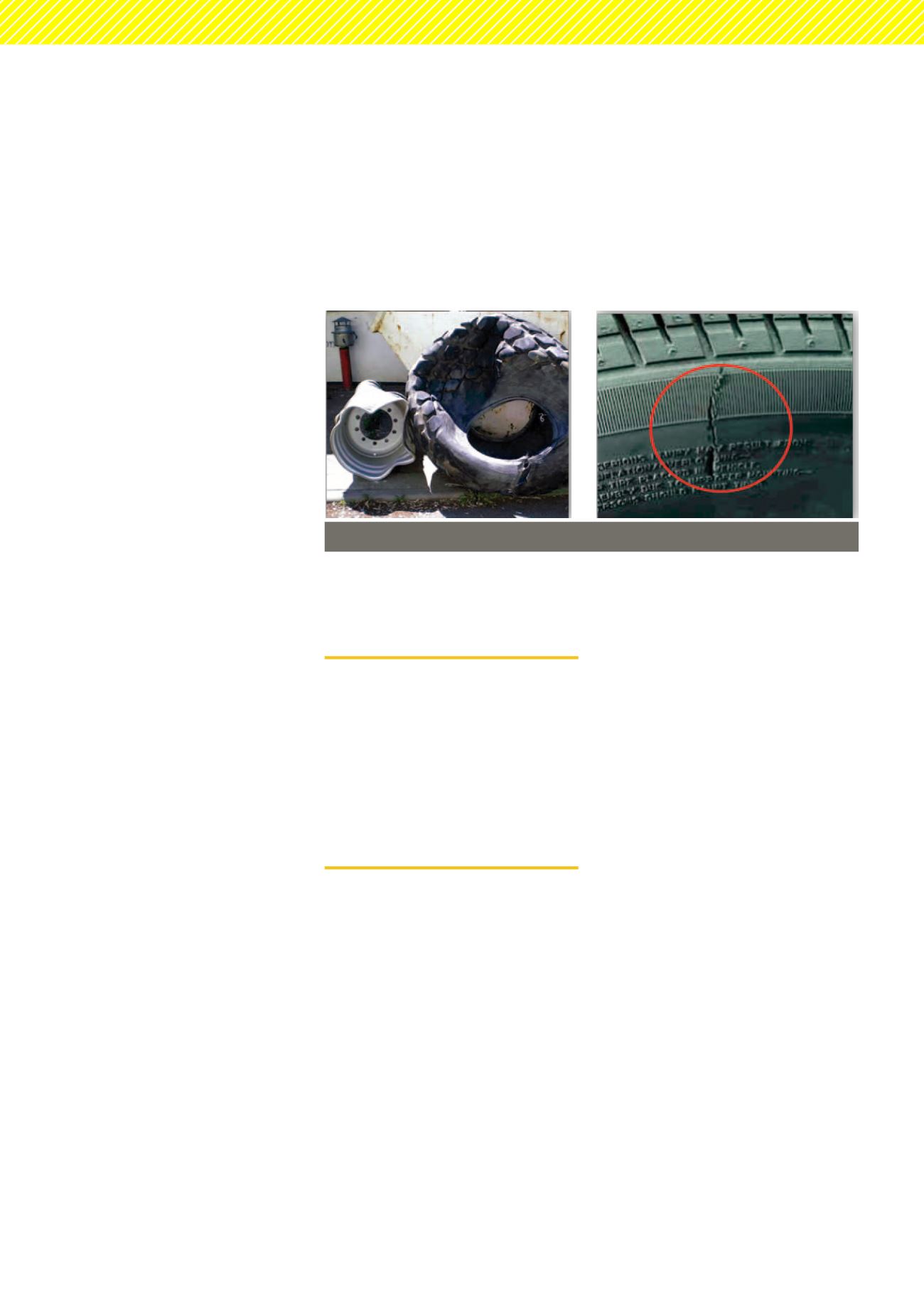

An example of the importance of properly

planning tyre replacement occurred

when a telehandler operator checked the

tyre pressures on his machine. Having

completed the checks, he was walking

away when one of the tyres exploded!

A subsequent investigation revealed the

tyre, which had recently been replaced,

was a 14 ply with a 3.5 tonne load

rating, rather than the manufacturer’s

specification of 16 ply with a six tonne

rating. The contractor also found the tyre

had been ordered from the company’s

approved supplier by asking for a

tyre for the model of the telehandler,

without mention of ply or load rating. A

subsequent check of other machines on

site found a third of them were fitted with

incorrect tyres.

The effect of tyres on stability

Tyres play a vital part in the stability of

telehandlers. Stability can be adversely

affected by issues such as:

• mixing tyres from different

manufacturers;

• incorrect ply rating;

• differences in diameter of tyres on the

same axle due to differential wear;

• low tyre pressure;

• high tyre pressure;

• uneven tyre pressure;

• substandard repairs;

• tyre repair, replacement and

maintenance for pneumatic tyres

only. Foam filled tyres are not user

serviceable.

Tyre pressure check

• Tyre pressures should be marked on

the chassis adjacent to each wheel.

• Pressures should be checked daily

ALERT – Tyres on Telehandlers

Issued by the TSHA December 2016

when cold.

• If necessary inflate tyres to

correct pressure as stated in the

manufacturer’s operators manual.

• Personnel inflating tyres should stand

a minimum of 3m away from the

tyre and outside the likely explosion

trajectory to avoid injury in the event

of a failure. This will require 3m of

airline between the nozzle and the

airline trigger mechanism.

• Personnel should ensure they stand

to one side of the tyre facing the tread

when inflating.

• Tyre valves should be checked to

ensure they are not leaking. Valve stem

caps should always be replaced.

Tyre damage

All tyres should be inspected daily as

follows:

• the tread and side walls should be

checked for bulges and separation;

• The tread and side wall should be

checked for cuts.

For pneumatic tyres, when any cut, rip or

tear is discovered that exposes sidewall

or tread area cords in the tyre, measures

must be taken to remove the tyre from

service immediately. Arrangements must

be made for replacement of the tyre or

tyre assembly.

Tyre and wheel replacement

Replacement tyres should be the same

size, ply and brand as originally installed;

refer to the appropriate parts manual

for ordering information. If not using an

approved replacement tyre, the tyres

must have the following characteristics:

• equal or greater ply and load rating

than size of original;

• tyre tread contact width equal or

greater than original;

• wheel diameter, width and offset

dimensions equal to the original;

• approved for the application by the

tyre manufacturer (including inflation

pressure and maximum tyre load).

Unless specifically approved by the

telehandler manufacturer, a foam filled

or ballast filled tyre assembly must not

be replaced with a pneumatic tyre. So

when replacing tyres ensure the ply and

pressure ratings are as per manufacturer

recommendations.

Visit:

www.tsha.com.auor contact the

national office on 02 9998 2222.

Did you know research undertaken by a major telehandler manufacturer indicates a 5%

reduction in tyre pressure from the manufacturer’s specified values can result in a 30%

reduction in capacity at certain points on the load/height/radius curve?

For pneumatic tyres, when any cut, rip or tear is discovered that exposes sidewall or tread area cords in

the tyre, measures must be taken to remove the tyre from service immediately

Personnel inflating

tyres should stand

a minimum of 3m

away from the tyre

and outside the likely

explosion trajectory to

avoid injury in the event

of a failure.