SAFE at WORK

56

HIRE AND RENTAL NEWS • AUGUST 2015

Hand–arm vibration (HAV) is vibration

transmitted to the hand and arm during

the operation of hand-held power tools

and hand-guided equipment, or holding

materials being processed by machines.

Hand–arm vibration is commonly

experienced by workers who regularly

use tools such as compaction equipment,

concrete vibrators, jackhammers,

chainsaws, garden care equipment,

grinders, drills etc. Painful and permanent

injury to hands and arms may result from

high levels of exposure to vibrations when

operating such equipment. HAV can cause

a range of conditions collectively known as

hand–arm vibration syndrome (HAVS) and

specific disorders such as carpal tunnel

syndrome, ‘tennis elbow’ and ‘vibration

white finger’.

HAV is quickly becoming a WHS issue

in the Australian construction market

and contractors need to take measures

to reduce the HAV exposure of their

employees. Presently there are no

mandatory exposure levels in Australia,

although in Europe there are mandatory

levels which may be used as a guide.

However employers need to ensure they

are making appropriate risk assessments

to limit employees' exposure to HAV.

HAV is measured where the operator holds

onto the machine and a measurement

is recorded. An example of recorded

measurement would read like

HAV 5.4m/s

2

. (5.4m per second squared).

Some equipment manufacturers print

these measurements in their operator’s

manual or even label their equipment

with HAV values to help guide their

customers. If not they should have

the figures available upon request. A

contractor should select tools that can be

used with the daily vibration exposure

of the operator remaining below 2.5m/s

2

averaged over an eight hour working day.

If this is not achievable, consider changing

or rearranging the task so this can be met.

Sometimes it is not possible to reduce

exposure to below 2.5m/s

2

however you

should never allow a worker to be exposed

to more than 5m/s

2

over an eight hour day.

How to reduce HAV exposure

Make an informed decision when

purchasing equipment. Do some research

and choose equipment that is designed to

help reduce lower HAV exposure.

TECH

TALK

Hand Arm Vibration (HAV)

Assess the risk and

manage the time

workers are using

equipment. Alternate

workers that are exposed

to higher HAV levels

when using equipment.

Train workers to

understand and

recognise their own

exposure levels, fatigue

and operating posture.

How manufacturers

are helping reduce

exposure to HAV while using their

equipment

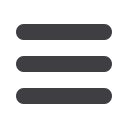

• The introduction of remote controlled

equipment has greatly reduced

operators' HAV exposure. Other benefits

include reduction in noise, exposure

to fumes, exposure to vibration when

using compaction equipment and

minimise exposure to trench collapse.

• Designing equipment for reduced HAV

levels, dampening operators handles

etc.

• Ergonomically designing equipment to

help reduce fatigue, for improved hand

and arm positioning.

• Labelling equipment to guide operators

as well as employers on the level of

HAV exposure.

Contact: 03 9549 0000 or visit website:

www.au.wackerneuson.comCapital Safety has launched

its new DBI-SALA Nano-Lok

Extended Length range of Self-

Retracting Lifelines (SRL’s).

Nano-Lok Extended Length

compact SRL’s provide extended

lifeline length when working at

height. The additional length

increases the anchorage options

and provides added mobility and

versatility where fall protection

is required.

“Depending on the model

selected, they provide up to 1.6m

more lifeline to the user, in a

compact, lightweight, easy-to-

use unit,” Rick Millar, Technical

Manager for Capital Safety

Australia & New Zealand said.

Belonging to the Nano-Lok

family, these new SRL’s have the

same feature set making them

compact and lightweight. They

can be used in place of lanyards

and directly attached to any

Extended length SRLs for added fall

protection versatility

harness, reducing fall clearances.

Designed for ease-of-use, these

SRL’s are unobtrusive to the

user when worn and provide the

ultimate in work site flexibility.

The new Nano-Lok Extended

Length range consists of two

single leg webbing lifeline models

with either a snap or scaffold hook

designed to cover the majority of

applications. DBI-SALA’s i-Safe

intelligent safety system utilising

RFID technology is built into each

Nano-Lok Extended Length SRL to

track inspections, control inventory

and manage information.

Capital Safety, a fall protection

company and a leading designer

and manufacturer of height safety,

confined space and industrial

rescue equipment with 20 operating

sites worldwide, is home of the DBI-

SALA and Protecta brands.

Contact: 1800 245 002 or visit:

www.capitalsafety.com.auHAV is quickly becoming a WHS issue in the Australian construction market