46

HIRE AND RENTAL NEWS • AUGUST 2015

EARTHMOVING + MINI EQUIPMENT

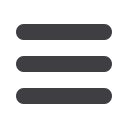

“This new model is ideal for general

handling in and around the building site

and because it can fit in spaces even

below 2m, accessing low height multi-

storey and basement car parks or confined

areas is easy,” Greg Sealey, JCB CEA

National Product Manager said.

“The new model replaces the previous

JCB Compact Loadall and has an improved

design that allows a 2,500kg lift capacity.

And the 6m lift height means it can safely

lift building materials to second-storey

building height.”

The chassis is a one piece design that

features 25mm thick chassis side plates,

making it strong and rigid while still

allowing for a tight turning circle when

working in confined spaces. The cab is

fitted with manual selectable 4WS, offering

a choice of front wheel, all wheel and crab

steer modes for increased manoeuvrability.

The 525-60 comes standard with JCB’s

patented technology software, Livelink,

which offers increased fleet monitoring

capabilities. The software delivers real-

time information on fleet management,

maintenance, run hours, and security

straight to a computer, tablet or mobile.

“LiveLink allows operators to work

smarter. It gives peace of mind your

machines are well maintained and in good

health without having to travel around

conducting inspections,” Greg said.

With safety a top priority for JCB, the

525-60 has a low boom pivot point for

increased visibility to the right hand front

and rear wheels, which is of paramount

importance when working in confined

areas. Also improving visibility is the low-

set bonnet, which gives off-side visibility.

The bonnet is specially designed to open

wide enough to give easy access to the

service points, all of which can be reached

from ground level.

The 525-60 is powered by a 55.4kW

(74hp) JCB Diesel by Kohler Tier 4 final

engine that doesn’t require any form of

after treatment such as AdBlue or diesel

particulate filter, reducing the cost of

maintenance and overall ownership.

The 525-60 was developed by JCB

in response to growing demand for a

smaller sized machine that delivers

reach capabilities that, in the past, have

New Loadall rivals larger machines

The next generation JCB 525-60 Hi-Viz Compact Loadall combines compact design with a

reach capacity to rival larger machines.

only been seen in larger

telehandlers.

“Versatility is the

number one feature that

can help ensure return

on investment when

purchasing equipment for

your operation,” Greg said.

“The more tasks each

model is suited for, the

greater your product

utilisation. That’s what

makes this generation

of Loadall telehandlers

superior.”

Contact: 02 9609 6033 or

visit:

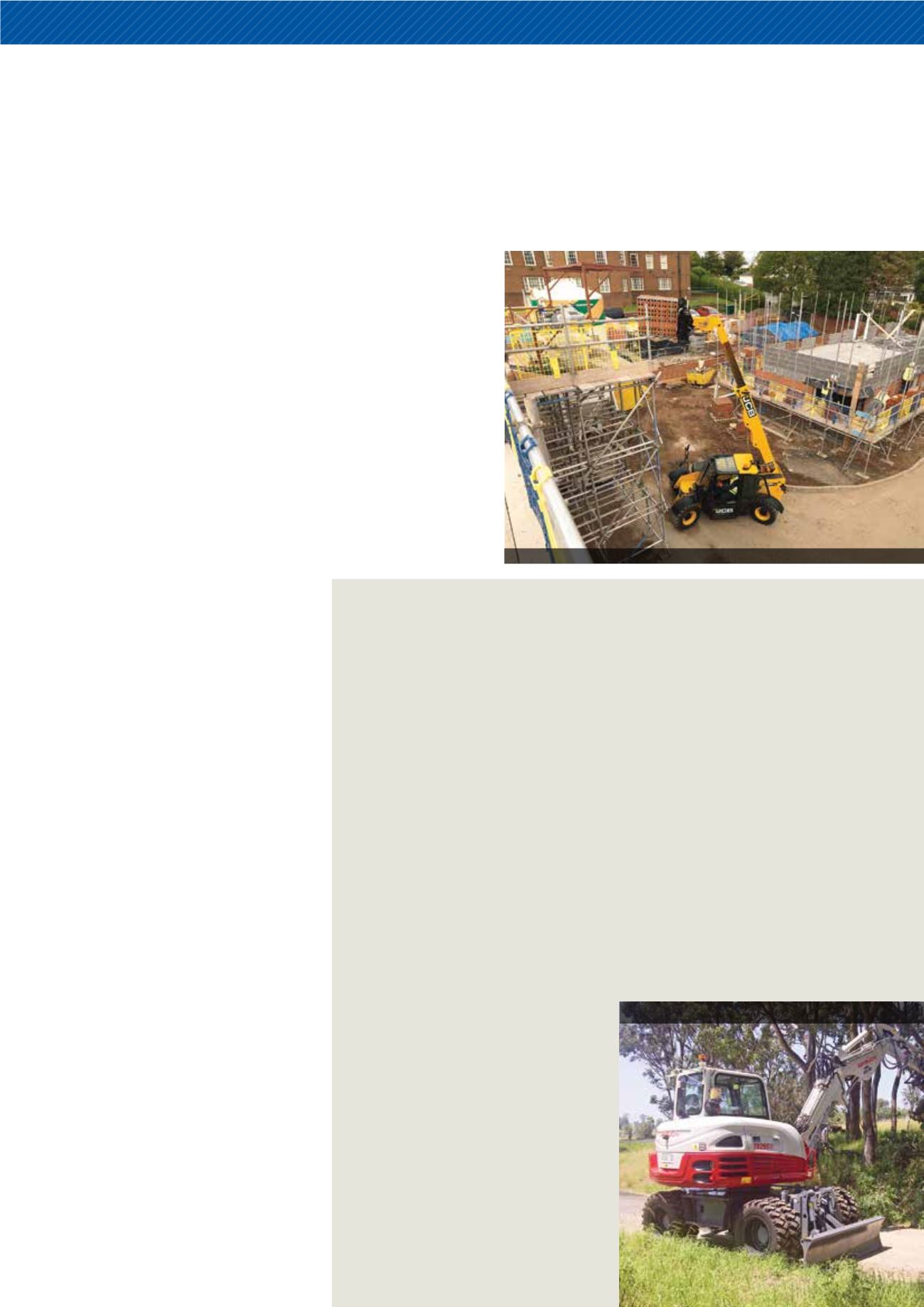

www.jcbcea.com.auRoadside vegetation control is an

ongoing challenge for regional councils

that have to manage intrusive growth,

often along more than 1000km of roads.

Excessive vegetation may obscure safety

signage or otherwise impact driver and

pedestrian visibility of intersections,

drains, poles and other infrastructure.

Outdated equipment or inappropriate

work practices may consume tightly

controlled financial and manpower

resources.

One regional Council has addressed this

challenge through the acquisition of a

Takeuchi TB295W 10tonne excavator

from Semco. This wheeled machine is

mobile on roads and is fitted with an

FAE DML/HY mulcher driven by the

excavator’s 45.5kW hydraulic flow that

optimises the power delivered to the

cutter head, leaving plenty in reserve to

handle other functions simultaneously.

The Council said its excavator/mulcher

combination has satisfied its need for

more efficient vegetation and drain

control. Physical demands on operators

may also be more demanding than

necessary through constantly craning

their necks for a clear view of vegetation

close to poles and wires. The excavator’s

two piece boom provides extraordinary

reach and control and permits working

in-close around the machine itself.

Efficient control of roadside vegetation

According to the Council, they have found

the excavator mulches heavier material

than before as their previous equipment

was more of a ‘groomer’ than a mulcher.

The excavator’s two knuckle boom is also

able to reach mulching height to remove

overhead tree growth to clear the way for

trucks and buses.

The TB 295W is performing multiple tasks

by using the quick hitch to change from

mulcher to mud bucket to clear drains,

needing only a few seconds to re-attach

the mulcher. While the excavator’s 30km

per hour road speed is a big bonus,

the Council said the greatest benefit is

increased productivity while keeping the

operator happy and more efficient.

Contact: 02 9833 6000 or visit website:

www.semcogroup.com.auTakeuchi TB295W on Council roads

The new JCB 525-60 telehandler is a compact machine that brings big power