ACCESS in ACTION

30

ACCESS IN ACTION • FEBRUARY 2017

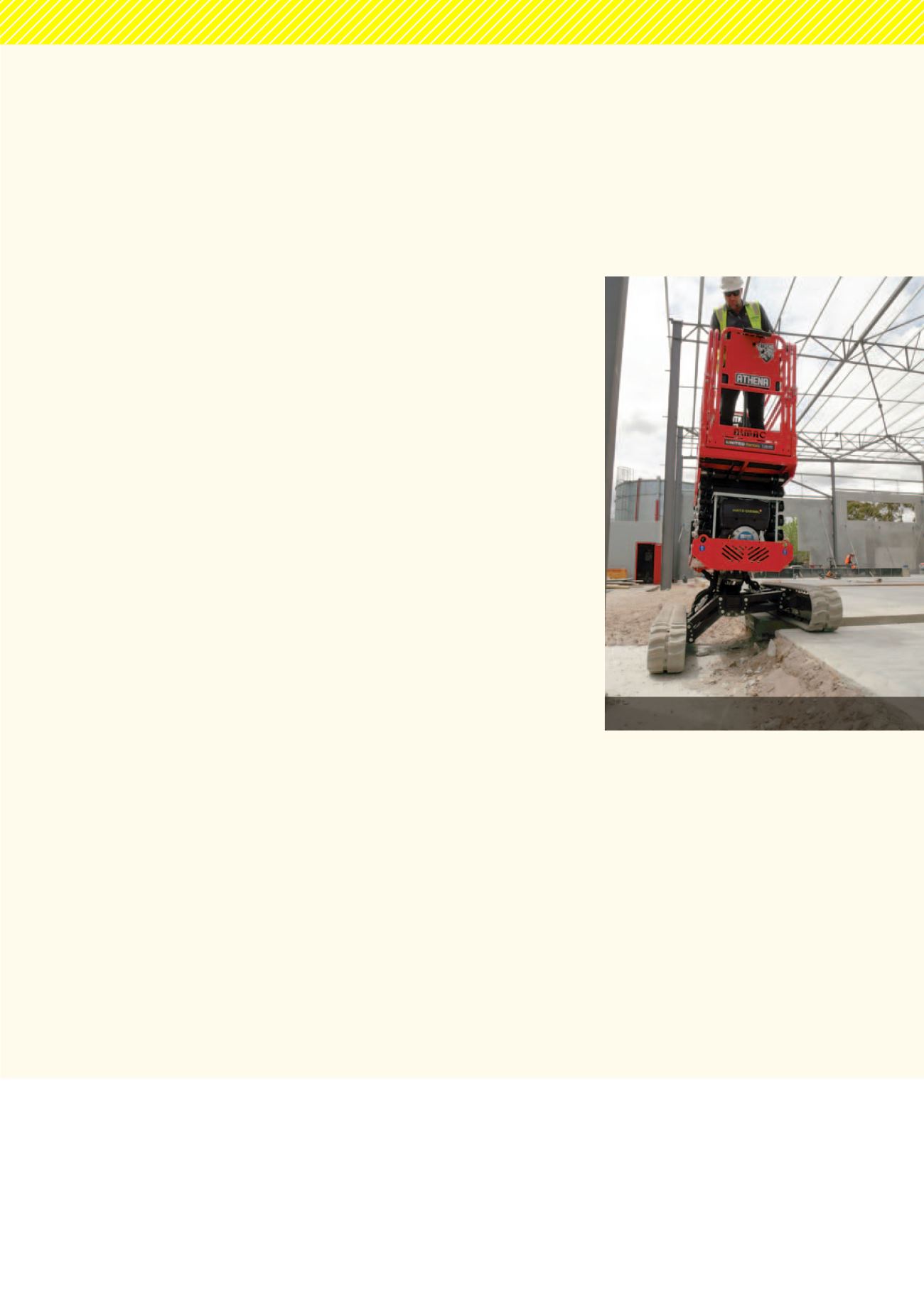

The Athena 850 bi-levelling tracked

scissor lift levels on its axis in longitudinal

and lateral directions to operate on

slopes and undulating terrain where

conventional scissor lifts cannot operate,

United Forklift and Access Solutions’

General Manager, Sales, Marketing and

Distribution, Trent Osborne said.

“Conventional scissor lifts are typically

limited to slight inclines of 2-4 degrees,

whereas the Athena 850 scissor lift

handles with assurance and safety, terrain

variations up to 50cm front and back and

38cm side-to-side on uneven terrain, or

inclines up to 20 degrees, Trent said.

“Marketed under the headline ‘the

only one of its kind in the universe,’ the

compact and versatile Athena 850’s

outstanding design and performance

won both the international (IAPA) and

HRIA Award, Best New Product of the

Year – Access for 2016. With a minimum

operating width of 1300mm, basket

capacity of 250kg and a maximum

working height of 7.9m, the machine has

many uses.

“Tracked scissor lifts already existed

before the Athena, but what makes

this machine unique is its bi-levelling

technology, which is found only on the

Athena,” Trent said.

“The Athena is built tough for indoor

and outdoor work, where its design and

functional superiority removes limitations

inherent in conventional mobile scissor

lifts. This greatly extends the machine’s

safety versatility and value in the

workplace.”

Safety, versatility and workplace

efficiency features include:

• Compliance with AS1418.10-2011;

Star tracked bi-levelling scissor lift offers new

dimensions of safety and value

A bi-levelling compact tracked scissor lift that can safely traverse slopes and terrain

where access equipment previously could not operate is being introduced to Australia by

United Forklift and Access Solutions.

• Gradeability of 25 degrees, side slope

21 degrees, operating and driving

safely on inclines of up to 20 degrees

with two-axis automatic levelling

constantly monitored to ensure safety;

• Elimination of concerns about

machines not being operable on-site

because of the slightest inclines or

the machine being too big or heavy

for the site conditions. Athena 850

weighs 1700/2190kg, depending on

specification and operates on steep

driveways, disabled access ramps,

footpaths and small access corridors;

• Elimination of many safety hazards

inherent in the common practice of

“packing the wheels” of scissor lifts on

job sites. This can create potentially

lethal situations where the accidental

flicking of a switch to ‘Drive forward’

instead of ‘Descend’ can turn into a

potentially fatal mistake;

• Ground clearance of up to 350mm

makes easy work of rough terrain,

urban obstacles and loading and

unloading without special trailers

tracks that operate independently so

operators can get in close;

• Automatic accelerator, bi-levelling

undercarriage, electrohydraulic

proportional commands, direction

control, easy drive system, automatic

control of inclination;

• Compact Hatz 1B40 diesel engine with

220V 2KW auxiliary electric pump and

220V 1KW power generator which

makes it possible to operate the scissor

lift indoors and in areas where the use

of combustion engines is not allowed;

• Kit for high speed (maximum 2.2kph);

• Onboard power source in the basket

for hand tools and lateral levelling

for moving at heights plus/minus 4

degrees.

“The Athena is simple to control and

extremely adaptable to difficult and

undulating terrain and worksites, indoors

and out. Its structure has been designed

to resist overload, with high-resistance

steel lifting mechanisms,” Trent said.

The Athena 850 scissor lift complements

United’s broader national ranges of forklift

and access equipment, including CAT

forklifts, Elevah personal stock pickers

and Konecranes lift trucks in capacities

up to 65tonnes.

Contact: 131 607 or visit website:

www.unitedequipment.com.auThe EWPA has been working with the

Australian Constructors Association

(ACA) on the safety of EWPs in the

construction industry. Machine

selection, operator training and product

familiarisation have been identified as

EWPA and the Australian Constructors Association collaborate

critical to safe operation of the EWPs. The

EWPA will launch its EWP Supervisor

course which will be a great tool for the

construction industry, where multiple

EWPs can be operating on site at any one

time. The ACA is able to provide direct

feedback from Tier One Construction

companies on issues relating to EWPs

and according to the EWPA, this

consultation process is very useful in

the production of training material and

guidance notes.

United Forklift and Access Solutions is

introducing the Athena 850 to its line up